- Equipment

- SOLTEQ®

- Software

- SOLDAS® IR 4.0

- SOLCAL® IR 4.0

- SOLTWIN® DIGITAL TWIN

.jpg)

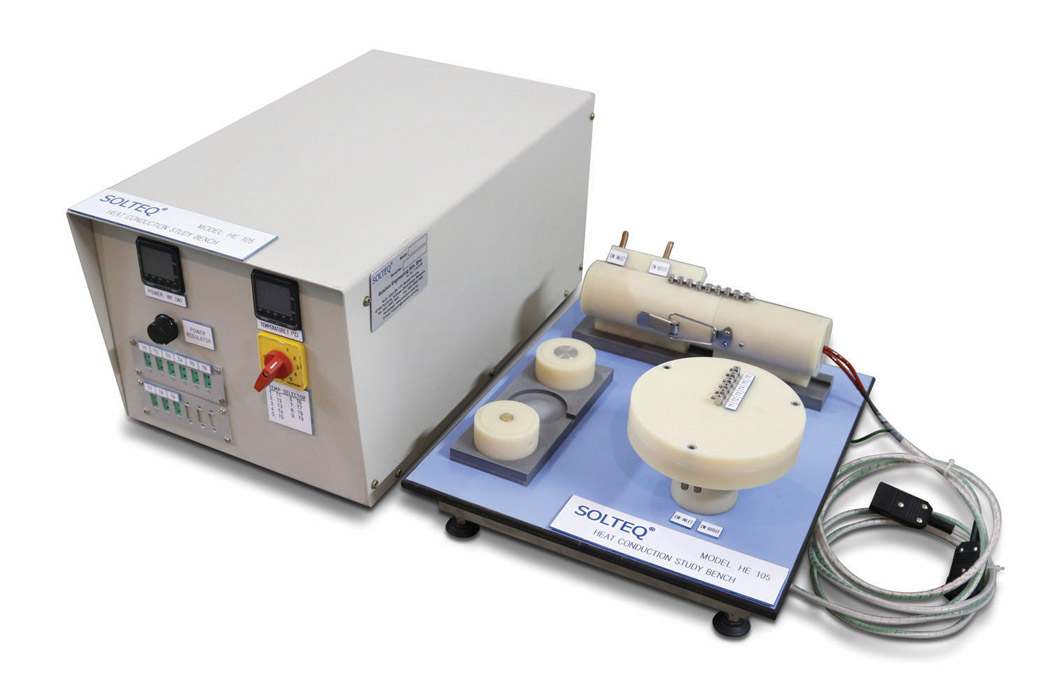

Equipment Name: Heat Conduction Study Bench

Model No: HE105

Click below to see example:Description: This Heat Conduction Study Bench is designed to provides an introduction into the concepts of heat conduction using one dimensional conduction modules. The linear test section is supplied with interchangeable samples of conductors and insulators.

This unit consists of:

Equipment Name: Free and Forced Convection Heat Transfer Unit

Model No: HE106

Click below to see example:Description: This Free and Forced Convection Heat Transfer unit is designed for demonstrates phenomena of natural (free) and force convection.

This unit consists of:

Equipment Name: Natural Convection and Radiation Unit

Model No: HE107

Click below to see example:Description: This Natural Convection and Radiation Unit is designed to allow students to study the phenomena of heat transfer over a range of pressures and vacuum, and to determine the emissivity value of the heater element.

This unit consists of:

Equipment Name: Forced Convection Heat Transfer Apparatus

Model No: HE108

Click below to see example:Description: This Forced Convection Heat Transfer Apparatus is designed for students to inspect hypothesis and associated formulae related to forced convection in pipes.

This unit consists of:

Equipment Name: Thermal Conductivity of Building Materials Apparatus

Model No: HE110

Click below to see example:Description: This Thermal Conductivity of Building Materials Apparatus is designed to determine the thermal conductivities of various building materials.

This unit consists of:

Experimental capabilities:

Equipment Name: Heat Transfer Service Unit

Model No: HE111

Click below to see example:Description: The Heat Transfer Service Unit can be connected to any of the seven optional heat transfer study units allow study of different modes of heat transfer.

The seven heat transfer study units are:

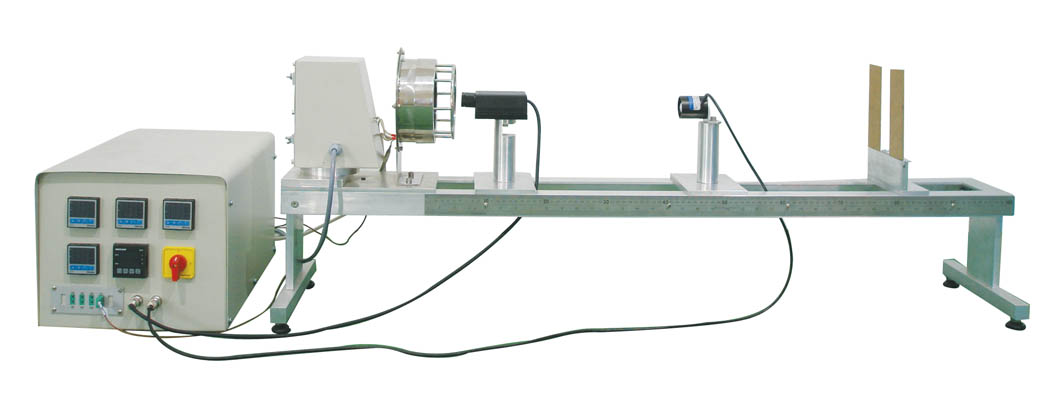

Equipment Name: Thermal Conductivity Experimental Apparatus

Model No: HE115

Click below to see example:Description: This Thermal Conductivity Experimental Apparatus is a bench mounting apparatus to allow students to demonstrate the conduction along the metal test specimens.

This unit consists of:

Experimental capabilities:

Equipment Name: Thermal Conductivity of Solid, Liquid and Gas

Model No: HE116

Click below to see example:Description: This Thermal Conductivity of Solid, Liquid and Gas is designed to determine the thermal conductivity of various solids, liquids and gases.

This unit consists of:

Experimental capabilities:

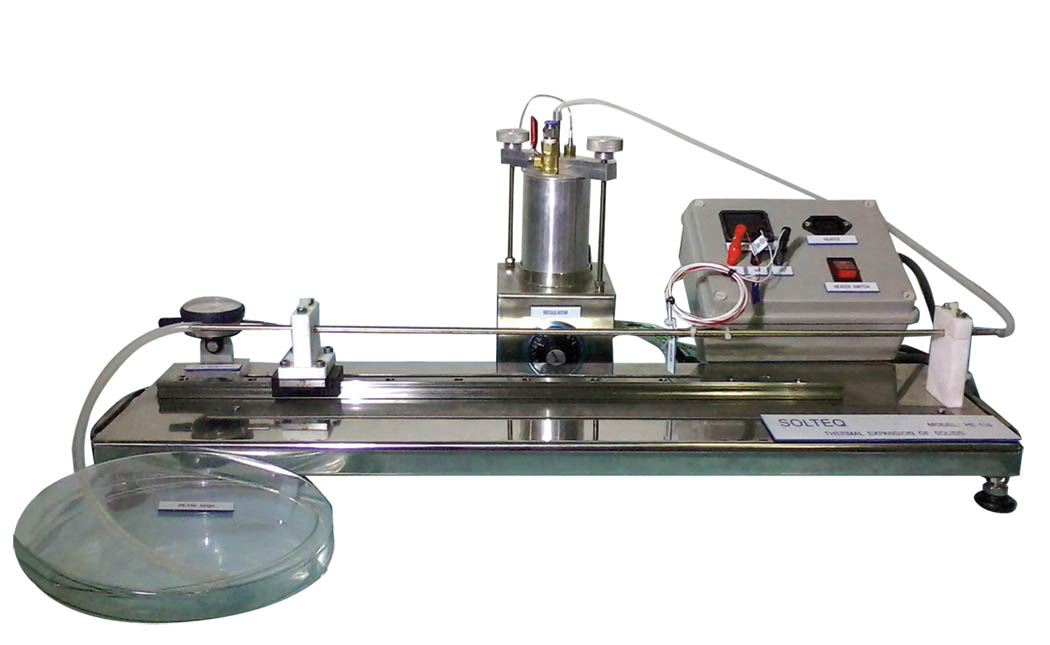

Equipment Name: Thermal Conductivity of Solids

Model No: HE118

Click below to see example:Description: This Thermal Expansion of Solids is designed to allow students to study the relationship between the length and the temperature of a solid.

This unit consists of:

Experimental capabilities:

Equipment Name: Temperature Measurement Apparatus

Model No: HE151

Description: This Temperature Measurement Bench is a complete, self-contained apparatus to demonstrate fundamental temperature measurement techniques.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow Boiling Heat Transfer Unit

Model No: HE153

Click below to see example:Description: This Flow Boiling Heat Transfer Unit is designed to provide students with a clear visual demonstration of what is happening inside the vapour generating tubes of practical plants.

This unit consists of:

Experimental capabilities:

Equipment Name: Pool Boiling Heat Transfer Unit

Model No: HE154

Click below to see example:Description: This Pool Boiling Heat Transfer Unit is designed for vividly demonstrates two regimens of boiling, namely nucleate boiling and film boiling.

This unit consists of:

Experimental capabilities:

Equipment Name: Radiation Heat Transfer Rig

Model No: HE155

Click below to see example:Description: This Radiation Heat Transfer Rig is designed to provides students with knowledge in the fundamental laws governing heat transfer by radiation, such as: Inverse Square law Kirchhoff's law Lamberts Cosine Law

This unit consists of:

Experimental capabilities:

Equipment Name: Thermal Conductivity of Liquids and Gases

Model No: HE156

Click below to see example:Description: This Thermal Conductivity of Liquid and Gases is designed to provides students with knowledge in the fundamental laws governing heat transfer by radiation, such as:

This unit consists of:

Experimental capabilities:

Equipment Name: Thermal Conductivity of Insulating Powder

Model No: HE157

Click below to see example:Description: This Thermal Conductivity of Insulating Powder unit is designed for allows the determination of thermal conductivity of insulating powder.

This unit consists of:

Experimental capabilities:

Equipment Name: Thermal Conductivity of Insulating Powder

Model No: HE157-A

Click below to see example:Description: This Thermal Conductivity of Insulating Powder unit is designed for allows the determination of thermal conductivity of insulating powder.

This unit consists of:

Experimental capabilities:

Equipment Name: Fluidisations and Fluid Bed Heat Transfer

Model No: HE162

Click below to see example:Description: This Fluidisations and Fluid Bed Heat Transfer Unit Unit is designed to provides visual understanding and quantitative results on the flow of air through both packed and fluidized bed of granular material.

This unit consists of:

Experimental capabilities:

Equipment Name: Film and Dropwise Condensation Unit

Model No: HE163

Click below to see example:Description: This Film and Dropwise Condensation Unit demonstrates two types of condensation processes, namely filmwise and dropwise condensation.

This unit consists of:

Experimental capabilities:

Equipment Name: Unsteady State Heat Transfer Unit

Model No: HE178

Click below to see example:Description: This Unsteady State Heat Transfer Unitis designed to allow students to run experiments on unsteady state heat transfer.

This unit consists of:

Experimental capabilities:

Equipment Name: Heat Transfer in Agitated Vessel

Model No: HE185

Click below to see example:Description: This Heat Transfer in Agitated Vessel is dedicated to introduce students to the study of heat transfer in an agitated vessel with coil and stirrer.

This unit consists of:

Experimental capabilities:

Equipment Name: Cross Flow Heat Transfer

Model No: HE350

Click below to see example:Description: This Cross Flow Heat Transfer is designed for assists students to understand the basic principles of cross flow heat transfer.

This unit consists of:

Experimental capabilities:

Equipment Name: Concentric Heat Exchanger

Model No: HE104

Click below to see example:Description: This Concentric Heat Exchanger is developed to investigate the fundamental principles of heat transfer applied to a classic two tubes heat exchanger.

This unit consists of:

Experimental capabilities:

Equipment Name: Plate Heat Exchanger

Model No: HE104-P

Click below to see example:Description: This Plate Heat Exchanger is designed to demonstrate the working principles of industrial heat exchangers.

This unit consists of:

Experimental capabilities:

Equipment Name: Shell & Tube Heat Exchanger

Model No: HE104-ST

Click below to see example:Description: This Shell & Tube Heat Exchanger is developed to investigate the fundamental principles of heat transfer as applied to a liquid-to-liquid heat exchanger.

This unit consists of:

Experimental capabilities:

Equipment Name: Heat Exchanger Training Apparatus

Model No: HE158C

Click below to see example:Description: This Heat Exchanger Training Apparatus is designed to familiarize students with different types of heat exchangers:

This unit consists of:

Experimental capabilities:

Equipment Name: Heat Exchanger Training Apparatus

Model No: HE158

Click below to see example:Description: This Heat Exchanger Training Apparatus is alternative model to HE158C, HE158 provides a jacketed stirred vessel heat exchanger in place of a shell and coiled tube heat exchanger.

This unit consists of:

Experimental capabilities:

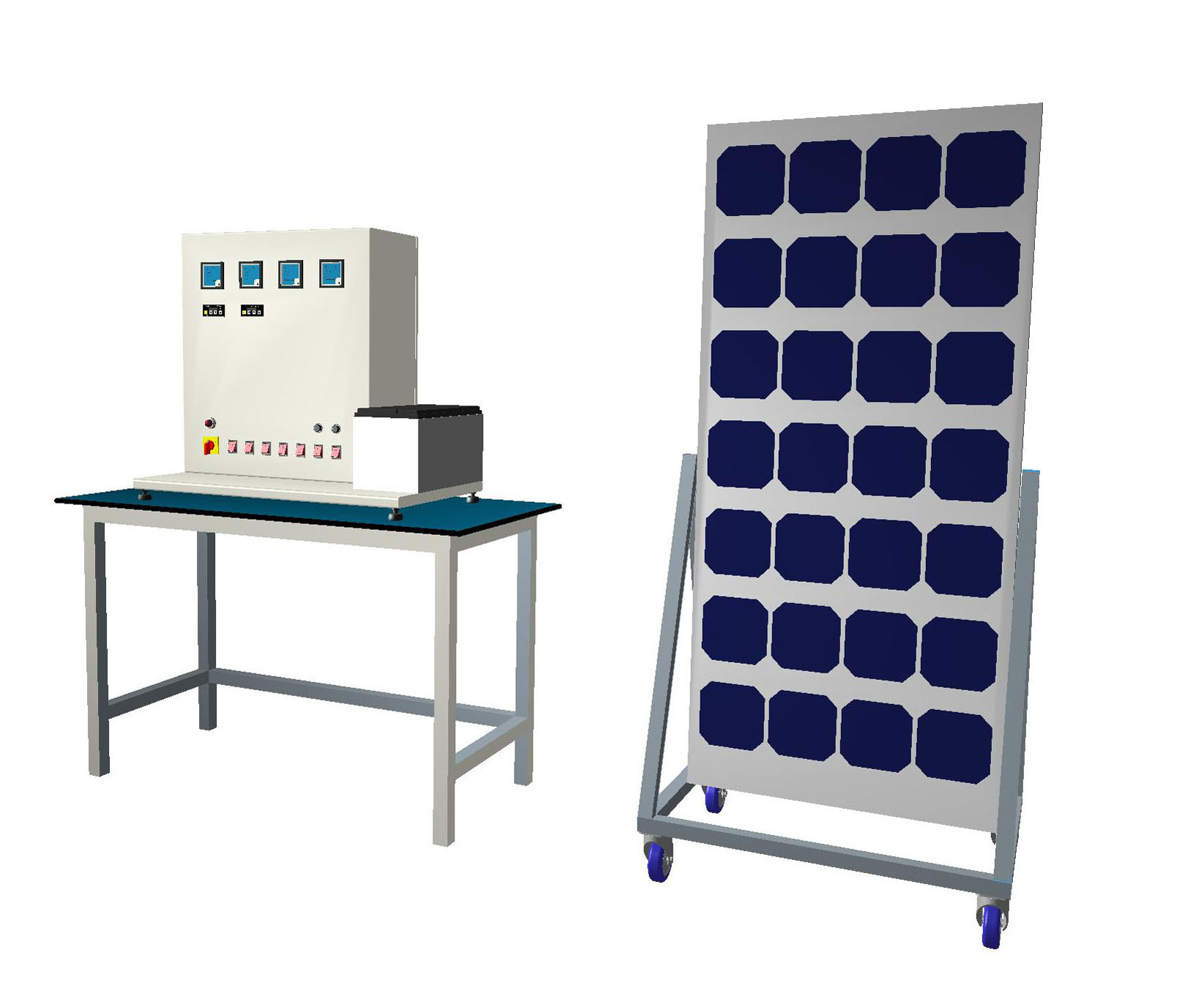

Equipment Name: Solar Energy Demonstration Unit

Model No: HE191

Click below to see example:Description: This Solar Energy Demonstration Unit is designed to demonstrate the principles of thermodynamics related to the field of solar energy. Students will be able to study the basic principles of the conversion of solar radiation into thermal energy.

This unit consists of:

Experimental capabilities:

Equipment Name: Plate Heat Exchanger

Model No: HE200

Click below to see example:Description: This Plate Heat Exchanger is designed to introduce students to the principles of a plate exchanger.

This unit consists of:

Experimental capabilities:

Equipment Name: Glass Shell and Tube Heat Exchanger Studies Units

Model No: HE667

Click below to see example:Description: This Glass Shell and Tube Heat Exchanger Studies Units is designed for alternative model to HE 668, the Glass Shell and Tube Heat Exchanger Studies Unit allows visual observation inside the heat exchanger. This unit can also be fitted with an air cooled radiator to recycle the heated water.

This unit consists of:

Experimental capabilities:

Equipment Name: Shell and Tube Heat Exchanger

Model No: HE668

Click below to see example:Description: This Shell and Tube Heat Exchanger is designed to introduce students to the principles of a shell and tube exchanger.

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Gauge Calibration Bench

Model No: FM01

Description: This Pressure Gauge Calibration Bench is a complete laboratory bench for test and calibration of various pressure measurement elements.

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Measurement Bench

Model No: FM01B

Description: This Pressure Measurement Bench is a complete laboratory bench for test and calibration of different types of pressure measurement elements.

This unit consists of:

Supplied with:

Equipment Name: Marcet Boiler

Model No: HE169

Click below to see example:Description: This Marcet Boiler is a bench top unit designed to demonstration the thermodynamic principles in a simple boiler.

This unit consists of:

Supplied with:

Equipment Name: Vapour Liquid Equilibrium Unit

Model No: BP16

Click below to see example:Description: This Vapor Liquid Equilibrium Unit is designed to investigate the relationship between vapour and liquid equilibrium at pressures up to 10 bar.

This unit consists of:

Supplied with:

Equipment Name: Temperature Measurement Apparatus

Model No: HE151

Description: This Temperature Measurement Bench is a complete, self-contained apparatus to demonstrate fundamental temperature measurement techniques.

This unit consists of:

Supplied with:

Equipment Name: Air Conditioning Laboratory Unit

Model No: AC01

Click below to see example:Description: The Air Conditioning Laboratory Unit is designed to demonstrate the working principles of air conditioning system.

This unit consists of:

Supplied with:

.JPG)

Equipment Name: Industrial Air Conditioning and Ventilation Unit

Model No: AC10

Click below to see example:Description: This Industrial Air Conditioning and Ventilation Unit is designed for complete training in principles of air conditioning and ventilation system. The unit is used to demonstrate the air conditioning processes and allows student to investigate the air recirculation and mixing, dynamic humidity, and temperature.

This unit consists of:

Experimental capabilities:

(1280-16-GPS)(6).JPG)

Equipment Name: Heat Pump Reverse Cycle

Model No: AC153

Description: This Heat Pump Reverse Cycle is designed for demonstration of reverse direction of basic refrigeration cycle used by an air conditioner.

This unit consists of:

Experimental capabilities:

(1280-16-GPS)(17).jpg)

Equipment Name: VRV System Simulation Unit

Model No: AC154

Description: This VRV System Simulation Unit is designed for demonstration of operation and performance if Variable Volume (VRV) type air conditioning

This unit consists of:

Experimental capabilities:

.jpg)

Equipment Name: Water Cooled Package Air Conditioner

Model No: AC155

Description: This Water Cooled Package Air Conditioner is installed with industrial type components to demonstrate the working principle of an actual air conditioning system.

This unit consists of:

Experimental capabilities:

(1233-15-SE)(1).jpg)

Equipment Name: Combustion Laboratory Unit

Model No: CO01

Click below to see example:Description: This Combustion Laboratory Unit is designed for study of combustion process using a small scale unit based on an industrial dual fuel burner.

This unit consists of:

Experimental capabilities:

(1156-14-SE)(5).jpg)

Equipment Name: Flame Propagation and Stability Unit

Model No: GE02

Description: This Flame Propagation and Stability Unit is specially designed for experiments on the characteristics of flames.

This unit consists of:

Experimental capabilities:

Equipment Name: Water Cooling Tower

Model No: HE152

Click below to see example:Description: This Water Cooling Tower is designed to demonstrate the operation of a force draught cooling tower.

This unit consists of:

Experimental capabilities:

(1347-17-SE)(13).jpg)

Equipment Name: Mechanical Heat Pump

Model No: HE165

Click below to see example:Description: This Mechanical Heat Pump is designed to provide students with a practical and quantitative demonstration of the vapour compression cycle.

This unit consists of:

Experimental capabilities:

(1220-15-SE)(Rev (1).jpg)

Equipment Name: Mechanical Heat Pump

Model No: HE165A

Click below to see example:Description: This Mechanical Heat Pump designed to provide students with a practical and quantitative demonstration of the vapour compression cycle.

This unit consists of:

Experimental capabilities:

Equipment Name: Refrigeration Laboratory Unit

Model No: RF01

Click below to see example:Description: This Refrigeration Laboratory Unit is designed to help students to study the performance of a vapour compression cycle under various conditions of evaporator load and condenser pressure.

This unit consists of:

Experimental capabilities:

(1343-17-SE)(7).jpg)

Equipment Name: Gas Absorption Refrigeration Unit

Model No: RF10

Click below to see example:Description: This Gas Absorption Refrigeration Unit is a laboratory benchtop unit for the demonstration of gas absorption refrigeration.

This unit consists of:

Experimental capabilities:

Equipment Name: Vapour Compression Refrigeration Trainer

Model No: RF108

Click below to see example:Description: This Vapour Compression Refrigeration Trainer is designed and constructed as a benchtop unit for students to study the thermodynamics of the vapour compression cycle.

This unit consists of:

Experimental capabilities:

Equipment Name: Vapour Compression Refrigeration Cycle

Model No: RF166

Click below to see example:Description: This Vapour Compression Refrigeration Cycle is designed and constructed as a benchtop unit for students to study the thermodynamics of the vapour compression cycle.

This unit consists of:

Experimental capabilities:

(1247-15-SE)(ok).jpg)

Equipment Name: Cascade Refrigeration Trainer System

Model No: RF169

Click below to see example:Description: This Cascade Refrigeration Trainer System has been designed with industrial type components to demonstrate the working principle of cascade refrigeration.

This unit consists of:

Experimental capabilities:

(1247-15-SE)(5).jpg)

Equipment Name: Air Conditioner Trainer

Model No: RF170

Click below to see example:Description: This Air Conditioner Trainer has been designed with industrial type components to demonstrate the working principle of an actual air conditioning system.

This unit consists of:

Experimental capabilities:

(1231-15-GPS)(1).jpg)

Equipment Name: Thermal Ice Storage Chiller System

Model No: RF171

Description: This Thermal Ice Storage Chiller System is installed with industrial type components to demonstrate the working principle of a thermal ice storage.

This unit consists of:

Experimental capabilities:

R.jpg)

Equipment Name: Boiler Simulator

Model No: TH01

Click below to see example:Description: This Boiler Simulator is designed to enable students to investigate parameters governing the utilization and maintenance of a thermal boiler.

This unit consists of:

Experimental capabilities:

(1149-14-SE)(1).jpg)

Equipment Name: Engine Test Bed

Model No: TH03

Click below to see example:Description: This Engine Test Bed is a floor mounted unit designed for the study of air cooled internal combustion engines

This unit consists of:

i) Four Stroke Petrol Engine

ii) Four Stroke Diesel Engine

Experimental capabilities:

(1216-15-SE) (3).jpg)

Equipment Name: Boyle’s Law Apparatus

Model No: TH10

Click below to see example:Description: This Boyle’s Law Apparatus is designed for demonstration of Boyle’s Law.

This unit consists of:

Experimental capabilities:

(1229-15-SE)(2).jpg)

Equipment Name: Perfect gas Expansion Apparatus

Model No: TH11

Click below to see example:Description: This Perfect gas Expansion Apparatus is a self-sufficient bench top unit designed to familiarize students with several fundamental thermodynamic processes. Demonstration of the thermodynamic processes is performed with air for a safe and convenient operation.

This unit consists of:

Experimental capabilities:

(1230-15-SE)(6)modify.jpg)

Equipment Name: Saturation Vapour Pressure Measurement Unit

Model No: TH14

Click below to see example:Description: This Saturation Vapour Pressure Measurement Unit is designed for study of the relationship between temperature and pressure of saturated vapour of boiling water.

This unit consists of:

Experimental capabilities:

(1211-15-SE)(1).jpg)

Equipment Name: Steam Motor & Energy Conversion Test Set

Model No: TH15

Click below to see example:Description: This Steam Motor & Energy Conversion Test Set is designed to introduce principles of thermodynamics and energy conversion to students. This unit is self-contained, with all components mounted within a robust and mobile epoxy coated frame.

This unit consists of:

Experimental capabilities:

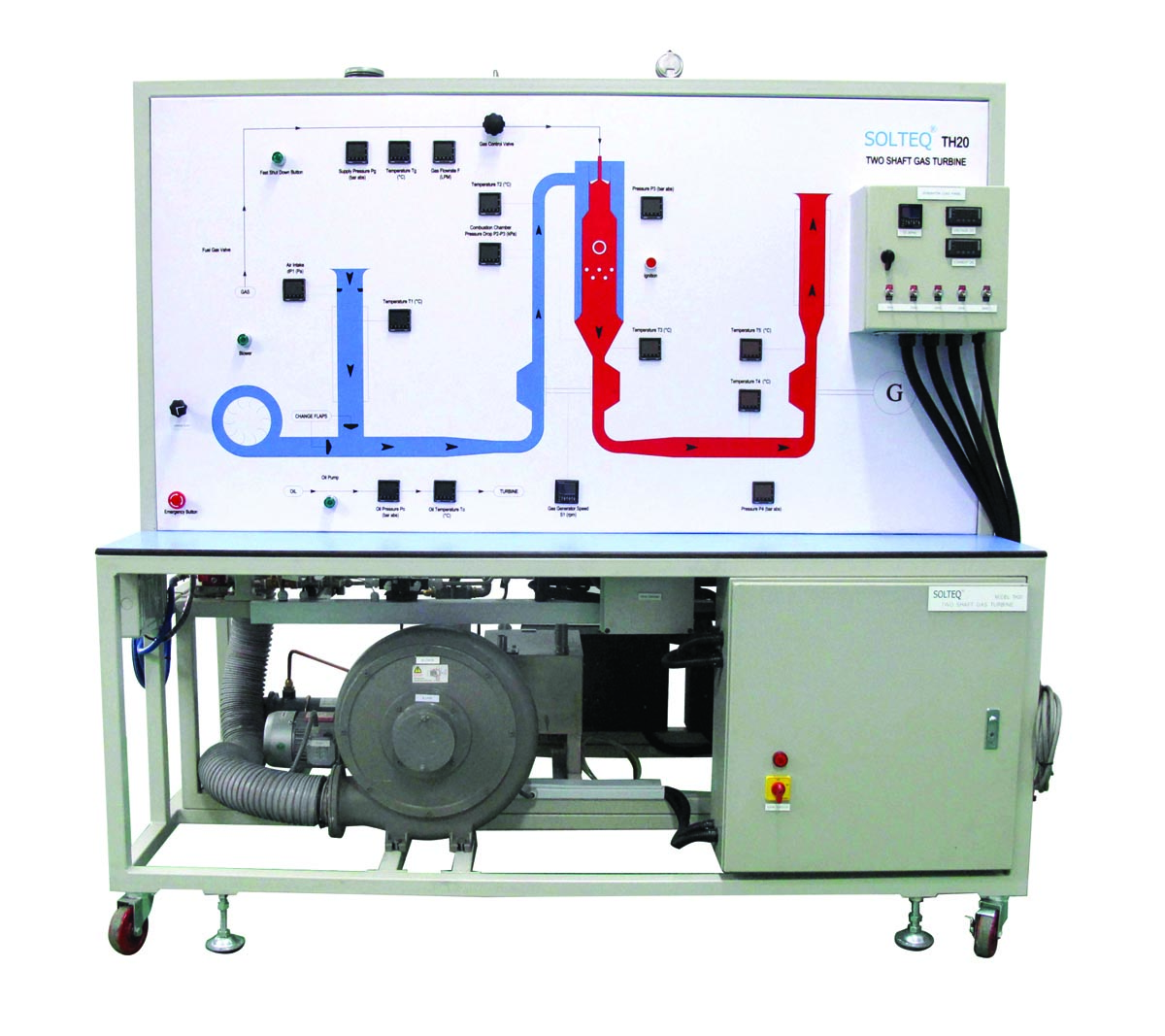

Equipment Name: Two-Shaft Gas Turbine Unit

Model No: TH20

Click below to see example:Description: This Two-Shaft Gas Turbine Unit is designed to provide the means for carrying out an extensive programme of experiments in gas turbine technology using the instrumentation provided.

This unit consists of:

Experimental capabilities:

i) Gas generator compressor

ii) Combustion chamber

iii) Power turbine

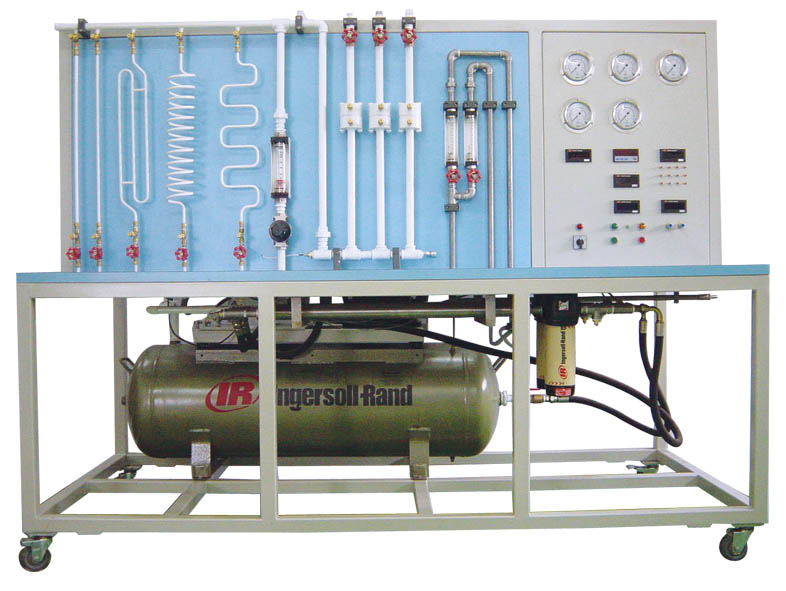

Equipment Name: Air Compressor Study Unit

Model No: WT01

Click below to see example:Description: This Air Compressor Study Unit is designed for the study of two-stage air compressor. The characteristics of compressed air flow through different types of flow arrangement are investigated.

This unit consists of:

Experimental capabilities:

Equipment Name: Two-Stage Air Compressor Apparatus

Model No: WT03

Click below to see example:Description: This Two-Stage Air Compressor Apparatus is designed to demonstrate the characteristics of single-stage and two-stage air compressor system.

This unit consists of:

Experimental capabilities:

Equipment Name: Instrumentation Calibration Bench

Model No: SE110-1

Description: This Instrumentation Calibration Bench is a complete laboratory bench for test and calibration of various instrument signals such as pressure, voltage and mA. High accuracy instrumentations such as pressure regulators and test gauges, digital meters are provided.

This unit consists of:

a) Instrument workbench

b) Instrument workbench console

Equipment Name: Smart Instrumentation Calibration Bench

Model No: SE110-2

Description: This Smart Instrumentation Calibration Bench is a complete laboratory bench for test and calibration of various instrument signals such as pressure, voltage and mA. High accuracy instrumentations such as pressure regulators and test gauges, digital meters are provided.

This unit consists of:

Instrument workbench

Instrument workbench console

Optional:

Smart Calibrator for:

.jpg)

Equipment Name: Experimental Stand For Flowmeters

Model No: SE111

Click below to see example:Description: This Experimental Stand For Flowmeters is designed to introduce student to various types of flow meters commonly found in industrial applications.

This unit consists of:

Experimental capabilities:

Equipment Name: Experimental Stand for Control Valves

Model No: SE112

Click below to see example:Description: This Experimental Stand for Control Valves is designed for demonstration of typical control valves characteristics.

This unit consists of:

Experimental Capabilities:

Equipment Name: Level Measurement and Calibration Experiment System

Model No: SE301

Description: This Level Measurement and Calibration is designed for students to study the principles of level measurement and site calibration.

This unit consists of:

Experimental capabilities:

Equipment Name: Density Measurement and Calibration Experiment System

Model No: SE302

Description: The Density Measurement and Calibration Experiment System is designed for students to study the principles of density measurement and site calibration.

This unit consists of:

Experimental capabilities:

(1338-17-SE)(4).jpg)

Equipment Name: Water Flow Measurement and Calibration Experiment System

Model No: SE303

Description: This Water Flow Measurement and Calibration Experiment System is designed for students to study various types of flow measurement devices as well as site calibration.

This unit consists of:

Experimental capabilities:

.jpg)

Equipment Name: Temperature Measurement and Calibration Experiment System

Model No: SE304

Description: This Temperature Measurement and Calibration Experiment System is designed to study the principles of temperature measurement as well as hands on experience on the configuration and calibration of transmitter. It demonstrates various temperature measurement methods and calibration used by industries.

This unit consists of:

Experimental capabilities:

Equipment Name: pH Measurement and Calibration Experiment System

Model No: SE306

Description: This pH Measurement and Calibration Experiment System is designed for students to study pH measurement and site calibration.

Experimental capabilities:

(1321-16-SE)(1).JPG)

Equipment Name: Temperature Measurement Bench

Model No: HE151

Description: This Temperature Measurement Bench is a complete, self contained apparatus to demonstrate fundamental temperature measuring and calibration techniques.

This unit consists of:

Experimental capabilities:

(1304-16-SE)(6).jpg)

Equipment Name: Pressure Measurement Bench

Model No: FM01B

Description: This Pressure Measurement Bench is a complete laboratory bench for test and calibration of different type of pressure measuring elements.

This unit consists of:

Experimental capabilities:

(1304-16-SE)(3).jpg)

Equipment Name: Flowmeter Measurement Apparatus

Model No: FM101

Description: This Flowmeter Measurement Apparatus is designed to introduce students to the operating characteristics of various types of flowmeters. The flowmeters are installed in a series configuration to permit comparison.

This unit consists of:

Experimental capabilities:

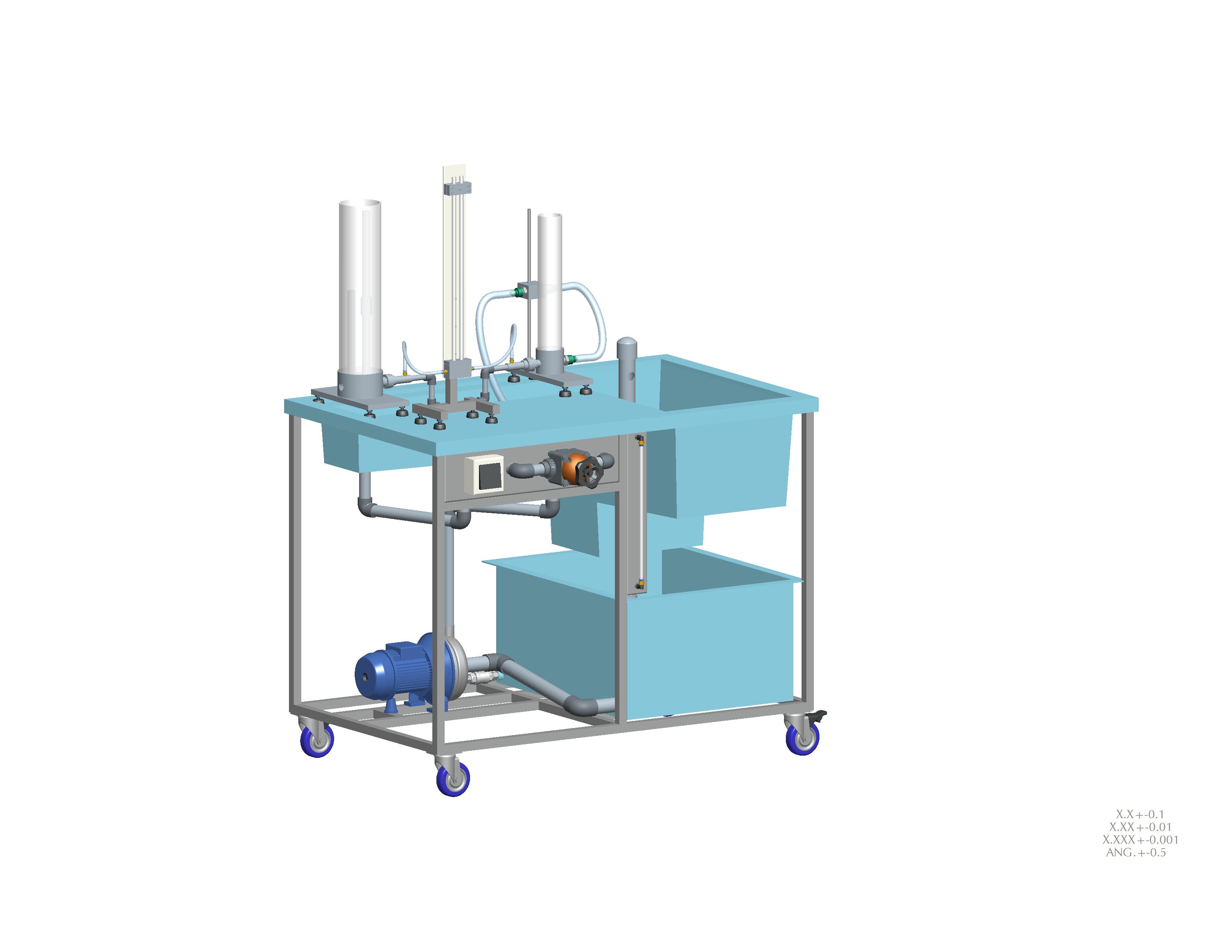

Equipment Name: Hydraulic Bench

Model No: FM110

Description: This Hydraulic Bench is designed to complement a wide range of accessories for experiments on the subjects of fluid mechanics. The unit consists of upper and lower mouldings mounted on a steel structure fitted with lockable wheels. The mouldings are made of fiberglass for lightweight and corrosion resistant features. An open channel and volumetric measuring tank are incorporated with the bench along with the means for mounting and connecting various accessories.

This unit consists of:

This unit consists of:

(1228-15-SE)(2).jpg)

Equipment Name: Demonstration 3-Term Controller unit

Model No: SE200

Description: This Demonstration 3-Term Controller unit is developed for introducing students to principles of pneumatic 3-term controller. The operations of differential bellows, feedback bellows, nozzle and flapper assembly, pneumatic relay are shown. A pressure process with control valve is included.

This unit consists of:

Experimental capabilities:

(1168-14-SE)(1).jpg)

Equipment Name: Process Control Simulator

Model No: SE201

Click below to see example:Description: This Process Control Simulator is designed to provide students with hands-on experience on control techniques. The unit will simulate a process containing three first order lags, two of which are changeable to pure integrators, plus an approximated distance velocity or transport lag. The unit consists of three main elements: the controller, the non-linear unit, and the process trainer unit.

This unit consists of:

Experimental capabilities:

(1268-16-SE)(3).jpg)

Equipment Name: Bench Top Process Control Trainer

Model No: SE202

Click below to see example:Description: This Refrigeration Laboratory Unit is designed to introduce students to basic control principles and theory of industrial process control system. The unit is a scaled down process model of an industrial process where flow, temperature and batch process control are commonly found. Optional level control and control valve can also be integrated into this system.

This unit consists of:

Experimental capabilities:

(1222-15-SE)(2).jpg)

Equipment Name: Bench Top Multiprocess Control Unit

Model No: SE229

Click below to see example:Description: This Bench Top Multiprocess Control Unit is designed to use water process for safe and practical experiments on flow, pressure, level and temperature control.

(1266-16-GPS) (1)modify.jpg)

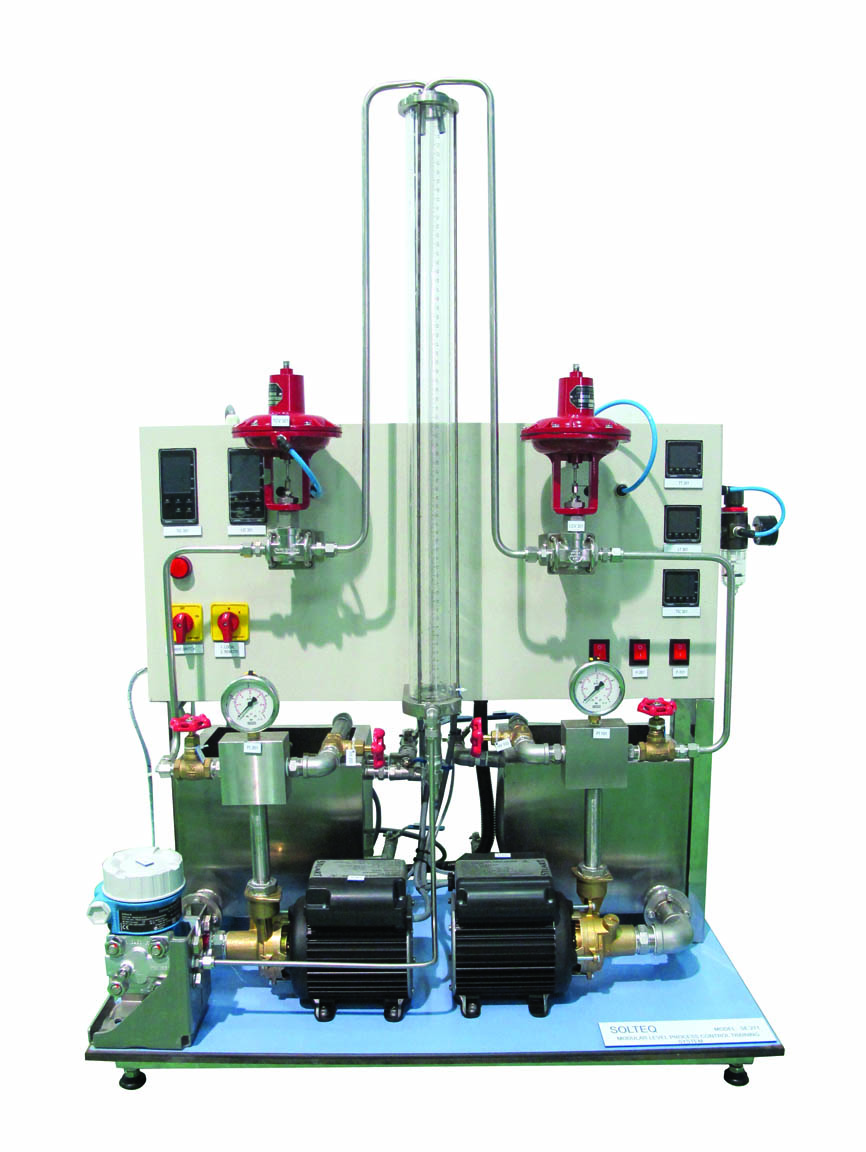

Equipment Name: Modular Flow Process Control Trainer

Model No: SE270-1

Click below to see example:Description: This Modular Flow Process Control Trainer is designed for the demonstration of flow control.

This unit consists of:

Experimental capabilities:

(1266-16-GPS)(1).jpg)

Equipment Name: Modular Level Process Control Trainer

Model No: SE270-2

Click below to see example:Description: This Modular Level Process Control Trainer is designed for the demonstration of level control.

This unit consists of:

Experimental capabilities:

Equipment Name: Modular Pressure Process Control Trainer

Model No: SE270-3

Click below to see example:Description: This Modular Pressure Process Control Trainer is designed for the demonstration of pressure control.

This unit consists of:

Experimental capabilities:

(1266-16-GPS)(2).jpg)

Equipment Name: Modular Temperature Process Control Trainer

Model No: SE270-4

Click below to see example:Description: This Air Conditioner Trainer is designed for the demonstration of temperature control.

This unit consists of:

Experimental capabilities:

Equipment Name: Modular pH Process Control Trainer

Model No: SE270-5

Click below to see example:Description: This Modular pH Process Control Trainer consists of a chemical waste treatment process where an alkaline is used to neutralize an acidic waste. The principles of pH measurement and control can be studied.

This unit consists of:

Experimental capabilities:

Equipment Name: Fire and Gas Detection System

Model No: SE109

Click below to see example:Description: This Fire and Gas Detection System is packaged for classroom training and demonstration in Field devices section and control section.

This unit consists of:

Experimental capabilities:

Equipment Name: Modular Level Process Control Training System

Model No: SE271

Click below to see example:Description: This Modular Process Control Trainer unit is designed to use water process for safe, practical experiments on water level control, and temperature control. The control process can either be carried individually or combined for MIMO control study.

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Control Trainer

Model No: SE401

Click below to see example:Description: This Pressure Control Trainer is designed to provide students with hands on experience on a pressure control loop using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow Control Trainer

Model No: SE402

Click below to see example:Description: This Flow Control Trainer is designed to provide students with hands on experience on a flow control loop using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1338-17-SE)modify.jpg)

Equipment Name: Level Control Trainer

Model No: SE403

Click below to see example:Description: This Level Control Trainer is designed to provide students with a better understanding on tank level measurement and control using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1184-14-SE) (36)modify.jpg)

Equipment Name: Temperature Control Trainer

Model No: SE404

Click below to see example:Description: This Temperature Control Trainer is designed for demonstration on how a temperature loop for a heat exchanger can be controlled using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1338-17-SE)(30).jpg)

Equipment Name: pH Control Trainer

Model No: SE405

Click below to see example:Description: This pH Control Trainer is designed to study principles of pH measurement and provide students with hands-on experience on how a pH loop can be controlled using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1145-14-GPS)(MODIFY).jpg)

Equipment Name: Analytical Control Trainer

Model No: SE105

Click below to see example:Description: This Analytical Control Trainer consists of an acid-alkali process anda self-contained chemical waste treatment process. It is designed to study the principles of measurement of typical industrial analytical parameters such as pH, ORP, conductivity and issolved oxygen. This plant also allows for the control of pH and conductivity.

This unit consists of:

Experimental capabilities:

(1266-16-GPS)(7) modify.jpg)

Equipment Name: Boiler Heating Batching Control Trainer

Model No: SE107

Click below to see example:Description: This Boiler Heating Batching Control Trainer consists of a liquid based process system design to study a simulated boiler drum producing hot water to heated the product water from a batching tank via a shell and tube heat exchanger.

This unit consists of:

Experimental capabilities:

(1266-16-GPS)(8)modify.jpg)

Equipment Name: Experimental Stand for Ratio Control

Model No: SE113

Click below to see example:Description: This Experimental Stand for Ratio Control is designed to introduce students to ratio control in relation to a single loop flow control.

This unit consists of:

Experimental capabilities:

Equipment Name: Air Pressure Control Trainer

Model No: SE121

Click below to see example:Description: This Air Pressure Control Trainer is designed to provide student with hands-on experience on how a pressure loop can be controlled using a microprocessor-based controller.

This unit consists of:

Experimental capabilities:

Equipment Name: Air Flow Control Trainer

Model No: SE122

Click below to see example:Description: This Air Flow Control Trainer is designed to provide students with hands-on experience on how an air flow loop can be controlled using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1266-16-GPS)(13)modify.jpg)

Equipment Name: Air Temperature Control Trainer

Model No: SE124

Click below to see example:Description: This Air Temperature Control Trainer is designed to provide students with hands-on experience on how a temperature loop of an air heat exchanger can be controlled using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

Air Pressure Control Trainer (Model: SE121), Air Flow Control Trainer (Model:SE122) and Air Temperature Control Trainer (Model:SE124) can be interconnected to form a bigger plant.

(1266-16-GPS)(13)modify.jpg)

Equipment Name: Heat Exchanger Control Trainer

Model No: SE134

Click below to see example:Description: This Heat Exchanger Control Trainer is designed to provide students with hands-on experience on how product temperature of a shell and tube heat exchanger can be controlled using a microprocessor based controller.

This unit consists of:

Experimental capabilities:

(1270-16-SE)modify.jpg)

Equipment Name: Process Trainer For Saline Solution Production

Model No: SE162

Click below to see example:Description: This Process Trainer For Saline Solution Production is developed primarily for teaching and research purpose. This process trainer is a small scale version of process plant that produces saline solution. It is used for produce saline solution in semi batch operation. The concentration of sodium chloride in the final product shall be made controllable to the user and shall be varied continuously ranging from 0.2%v/v to 1.0%v/v.

Experimental capabilities:

Equipment Name: Steam Condensation Unit

Model No: SE182

Click below to see example:Description: This Steam Condensation Unit is designed to allow students to have an overview on the effect of cooling water flowrate on the condensation of steam. The flow of cooling water will be regulated by using a control valve with PID input. Fuzzy Logic controller is optional for the equipment with additional requirement MATLAB and Fuzzy Logic Toolbox.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow and Pressure Control Trainer

Model No: SE664

Click below to see example:Description: This Flow and Pressure Control Trainer is designed for demonstration of the functionality of microprocessor based controller. The equipment exhibits a realistic working environment of a typical flow process using various types of industrial grade instruments and control strategy.

This unit consists of:

Experimental capabilities:

(1319-16-SE)(23).jpg)

Equipment Name: Flow and Level Control Trainer

Model No: SE665

Description: This Level and Flow Control Trainer is designed to provide students with a better understanding on control studies of level and flow control. It can also be coupled with a flow metering loop to enable cascade control studies.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow and Temperature Control Trainer

Model No: SE666

Click below to see example:Description: This Flow and Temperature Control Trainer is designed to provide students with a better understanding on how flow and temperature processes can be controlled.

This unit consists of:

Experimental capabilities:

.jpg)

Equipment Name: Continuous Distillation Column with Process Control

Model No: SE999

Click below to see example:Description: This Continuous Distillation Column is designed and constructed with the intention of exploring the behaviour and performance of various control strategies employed in a distillation process.

This unit consists of:

Experimental capabilities:

(1336-17-SE)(3).jpg)

Equipment Name: Cavitation Demonstration Unit

Model No: FM10

Description: This Cavitation Demonstration Unit has been designed to demonstrate to students the phenomenon of cavitation.

This unit consists of:

Optional:

Smart Calibrator for:

(1328-17-SE)(11).jpg)

Equipment Name: Osborne Reynolds Demonstration

Model No: FM11

Description: This Osborne Reynolds Demonstration is designed to reproduce the classic experiments by Professor Osborne Reynolds on visualization of fluid flow.

This unit consists of:

Experimental capabilities:

(1287-16-SE)(25).jpg)

Equipment Name: Orifice Discharge

Model No: FM12

Description: This Orifice Discharge is designed to demonstrate the measurement of orifice discharge.

This unit consists of:

Experimental Capabilities:

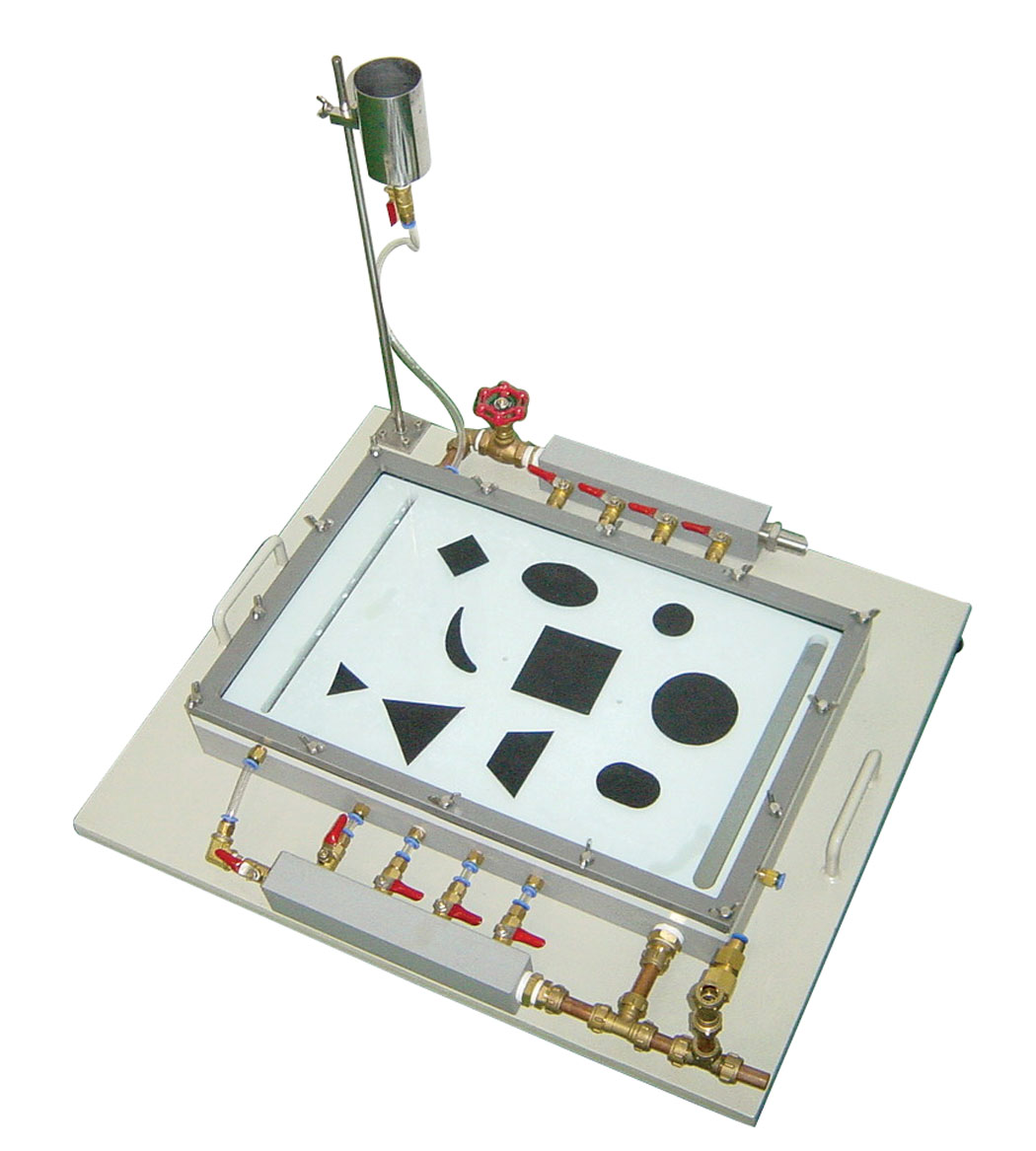

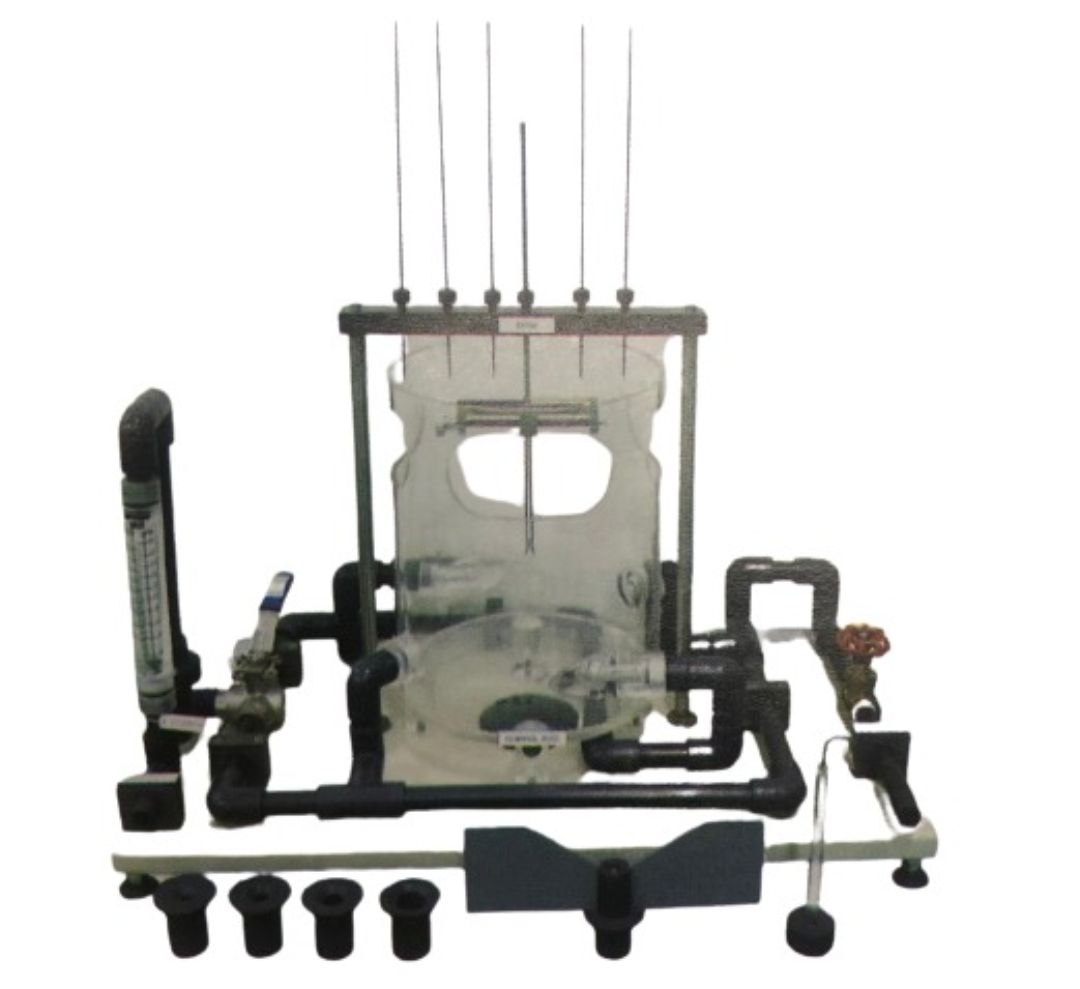

Equipment Name: Flow Visualisation Apparatus

Model No: FM22

Description: This Flow Visualisation Apparatus is designed to provide flow visualization of various drag bodies.

This unit consists of:

Experimental capabilities:

During the experiment, ink is injected through a fine nozzle to the flow chamber.

(1348-17-GPS)(4).jpg)

Equipment Name: Bernoulli’s Theorem Demonstration Unit

Model No: FM24

Description: The Bernoulli’s Theorem Demonstration unit is designed to demonstrate the principles of Bernoulli’s theorem.

This unit consists of:

Experimental capabilities:

(1153-14-SE)(2)modify.jpg)

Equipment Name: Orifice and Jet Flow Unit

Model No: FM25

Description: This Orifice and Jet Flow Unit is designed to demonstrate measurement of orifice discharge and jet flow.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow Over Weirs

Model No: FM26

Description: This Flow Over Weirs apparatus comes with two weir plates of different shapes, allowing familiarisation and comparison with weir theory. The unit is capable to demonstrate flow characteristic cover.

This unit consists of:

Experimental capabilities:

I. Rectangular notch

II. Vee (V) notch

(1220-15-SE)(11).JPG)

Equipment Name: Impact of Jet Apparatus

Model No: FM31

Description: This Impact of Jet Apparatus is designed for study on the force developed by a water jet impinging on different non-moving targets

This unit consists of:

Experimental capabilities:

(1316-16-SE)(1).jpg)

Equipment Name: Hydraulic Ram

Model No: FM39

Description: This Hydraulic Ram comprises a cast iron base incorporating pulse and non-return valves and a supply reservoir on a stand which is fed by the Hydraulic Bench. An air vessel above the valve chamber smooth cyclic fluctuations from the ram delivery.

This unit consists of:

Experimental capabilities:

(1287-16-SE)(5)modify.jpg)

Equipment Name: Venturi Meter

Model No: FM40

Description: This Venturi Meter is designed for experiments on the usage of a venturi. The venturi test piece has a circular cross section and is accurately machined from clear acrylic material with pressure measurement tappings at the converging/diverging sections and throat.

This unit consists of:

Pressure/Vacuum pump and tanks are also provided.

Experimental capabilities:

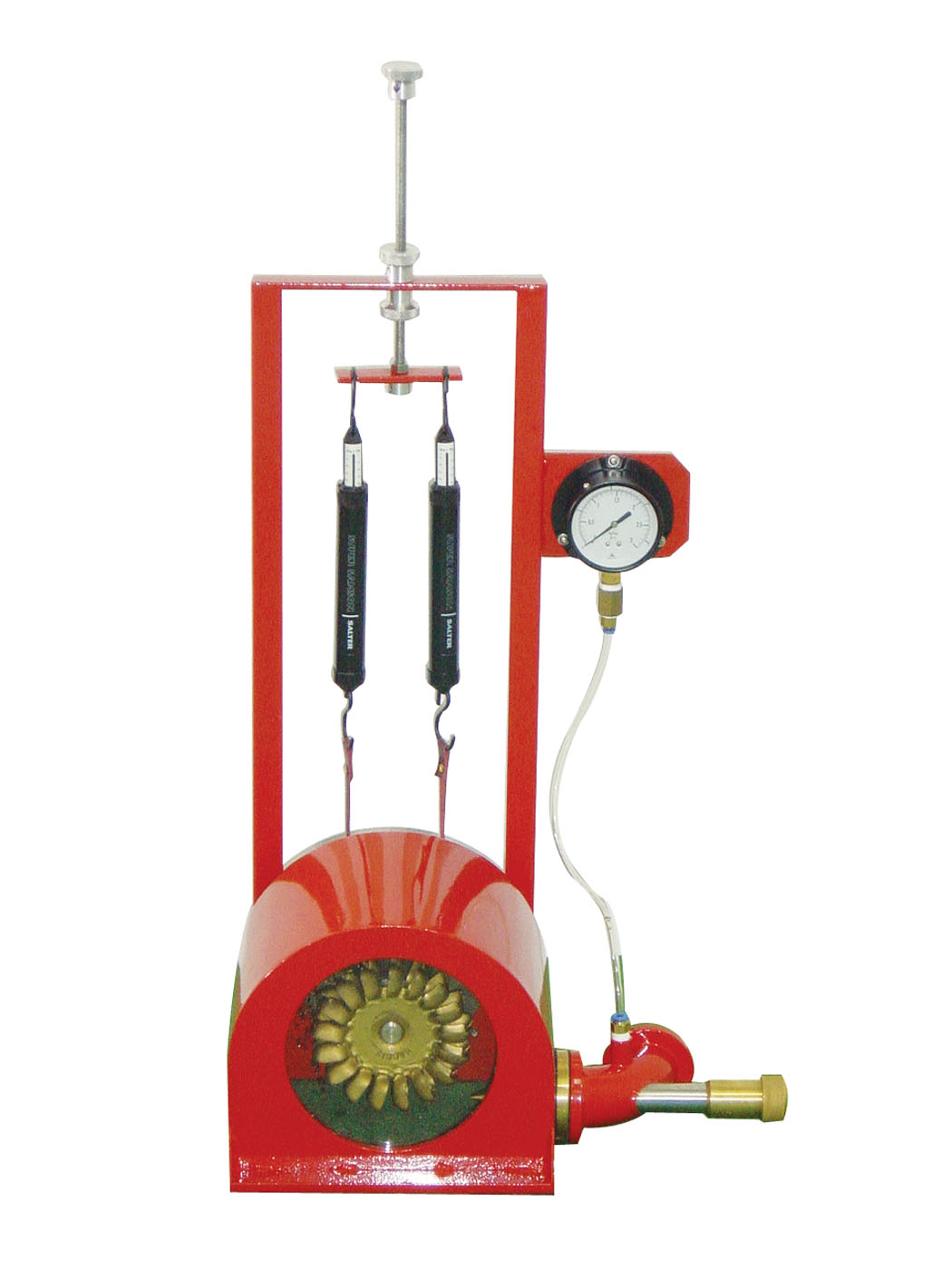

Equipment Name: Demonstration Pelton Turbine

Model No: FM41

Description: This Demonstration Pelton Turbine unit provides a simple low cost introduction to turbine performance.

This unit consists of:

Experimental capabilities:

Equipment Name: Free & Force Vortex

Model No: FM42

Description: This Free & Force Vortex is designed to generate and measure free and forces vortices.

This unit consists of:

Experimental capabilities:

(1246-15-GPS)(modify).jpg)

Equipment Name: Pipe Friction Apparatus

Model No: FM111

Description: This Pipe Friction Apparatus is designed for students to measure pipe friction losses for laminar and turbulent flows.

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Gauge Calibration Bench

Model No: FM01

Description: This Pressure Gauge Calibration Bench is a complete laboratory bench for pressure gauge calibration.

Three different types of pressure gauges are provided:

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Measurement Bench

Model No: FM01B

Description: This Pressure Measurement Bench is a complete laboratory bench for test and calibration of different types of pressure measuring elements.

This unit consists of:

Pressure/Vacuum pump and tanks are also provided

Experimental capabilities:

(1250-15-GPS)(43).jpg)

Equipment Name: Properties of Fluids and Hydrostatics Bench

Model No: FM02

Description: This Properties of Fluids and Hydrostatics Bench is a self contained and mobile bench equipped with all necessary apparatus for a comprehensive range of experiments on the properties and basic principles of fluids.

This unit consists of:

Basic Principle of Fluids

Experimental capabilities:

Equipment Name: Pipe Surge and Water Hammer Apparatus

Model No: FM04

Description: This Pipe Surge and Water Hammer Apparatus is designed for experiments on the transient effects of pipe surge and water hammer as a result of gradual or instantaneous changes in fluid velocity.

This unit consists of:

Experimental capabilities:

(1237-15-SE)(modify2).jpg)

Equipment Name: Serial/Parallel Pump Test Rig

Model No: FM07A

Click below to see example:Description: This Serial/Parallel Pump Test Rig is designed to demonstrate to students the operating characteristic of centrifugal pump in single configuration, series configuration & parallel configuration. Basic instruments are included to monitor the pump speed, pump head and flow rate.

This unit consists of:

Experimental capabilities:

(1293-16-SE)(21).jpg)

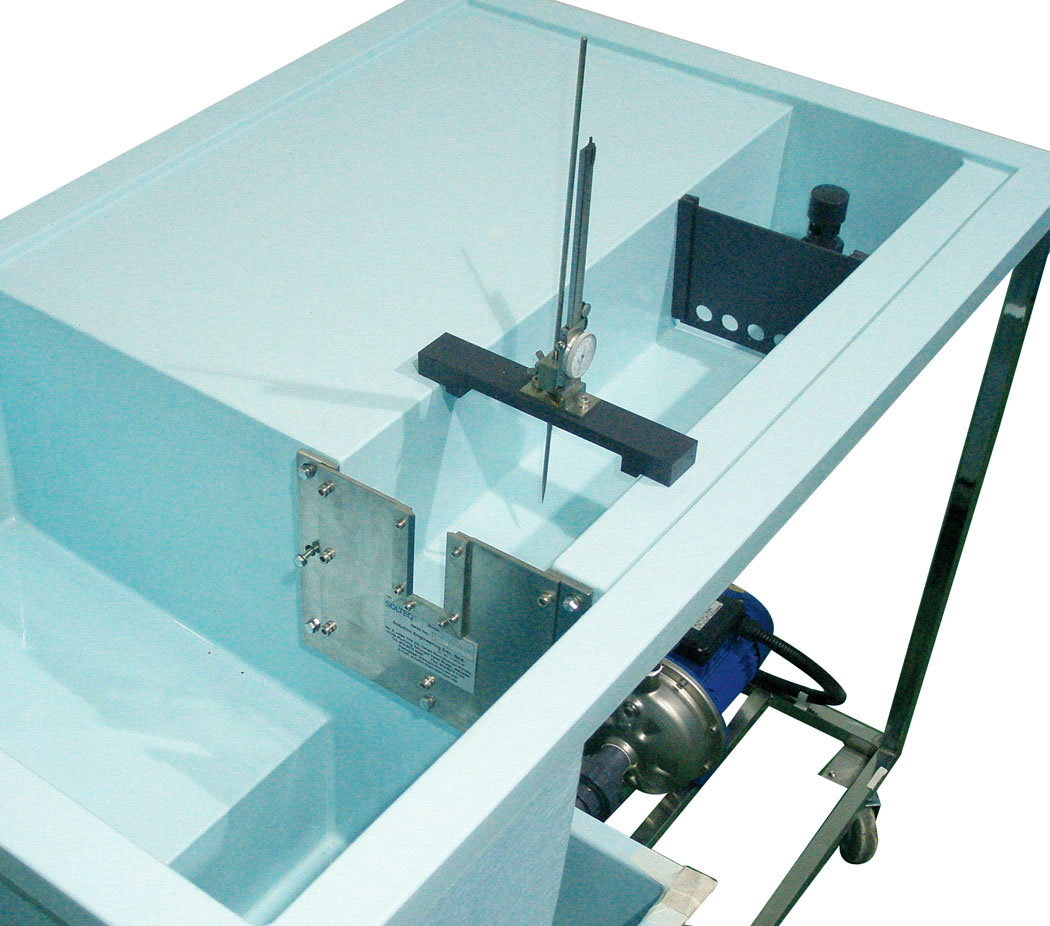

Equipment Name: Laminar Flow Table

Model No: FM23

Description: This Laminar Flow Table is designed to simulate ideal fluid flow and give clear visualization of the flow patterns created using water as the working fluid. This enables a comprehensive investigation into the principles of potential flow and allows modeling appropriate physical systems.

This unit consists of:

Experimental capabilities:

(1187-14-SE) (12).JPG)

Equipment Name: Hydrostatic Pressure

Model No: FM35

Description: This Hydrostatic Pressure apparatus is designed to introduce the concept of centre of pressure of an object immersed in fluid.

This unit consists of:

Experimental capabilities:

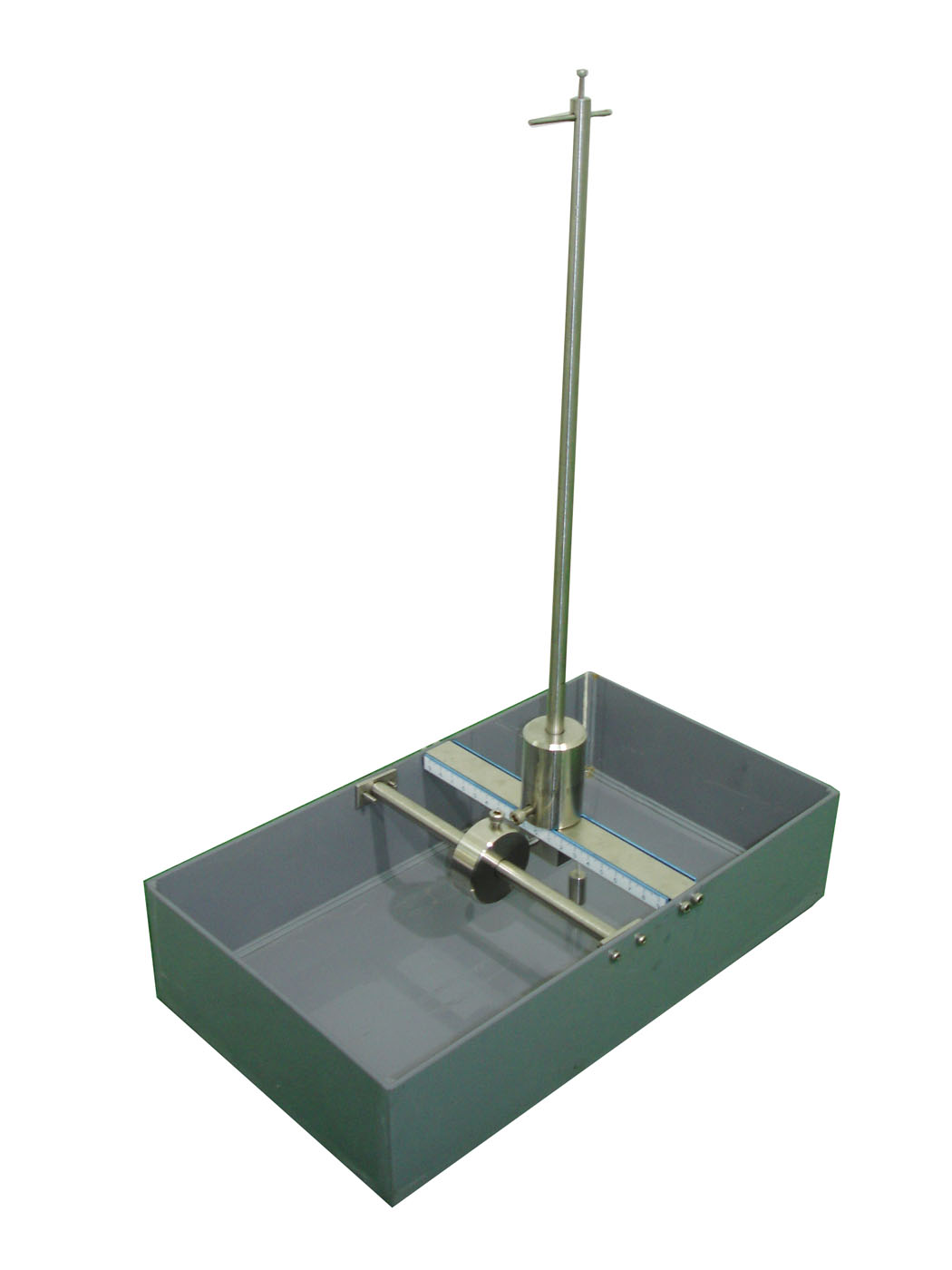

Equipment Name: Metacentric Height

Model No: FM43

Description: This Metacentric Height allows a thorough investigation of factors affecting the stability of a floating body.

Experimental capabilities:

.jpg)

Equipment Name: Dead Weight Pressure Calibrator

Model No: FM44

Description: This Dead Weight Pressure Calibrator is designed to demonstrate calibration of a Bourdon type pressure gauge.

This unit consists of:

Experimental capabilities:

(1264-15-GPS)modify.jpg)

Equipment Name: Pitot Static Tube

Model No: FM50

Description: This Pitot Static Tube is designed for students to determine the change in flow speed within a tube cross-sectional.

This unit consists of:

Experimental capabilities:

(1152-14-SE)(3).jpg)

Equipment Name: Particle Drag Coefficient Apparatus

Model No: FM102

Description: This Particle Drag Coefficient Apparatus is designed to introduce the fundamental characteristics of particle / fluid systems, in particular the relationship between drag coefficients of falling particles and Reynolds number.

This unit consists of:

Experimental capabilities:

(1215-15-SE)(1).jpg)

Equipment Name: Liquid Mixing Equipment

Model No: FM103

Click below to see example:Description: This Liquid Mixing Equipment is a benchtop unit designed for visualization of solid/liquid and liquid-liquid mixing.

This unit consists of:

Experimental capabilities:

(1287-16-SE)(8).jpg)

Equipment Name: Gravimetric Hydraulic Bench

Model No: FM110-G

Description: This Gravimetric Hydraulic Bench is designed for students to control water flow in a wide variety of laboratory experiments via gravimetric weighing system.

This unit consists of:

(1220-15-SE)(13).JPG)

Equipment Name: Energy Losses in Bend and Fittings

Model No: FM34

Description: This Energy Losses in Bend and Fittings is designed for investigation of energy losses in pipe bends and fittings, including valves. This will enable students to appreciate energy losses associated with different devices.

This unit consists of:

Experimental capabilities:

Equipment Name: Losses In Pipes and Fittings Apparatus

Model No: FM36

Description: This Losses In Pipes and Fittings Apparatus is designed for students to energy losses in pipes and fittings including valves.

Experimental capabilities:

(1181-14-SE)(1).jpg)

Equipment Name: Pipe Network Apparatus

Model No: FM06

Description: This Pipe Network Apparatus is designed for students to measure flows and pressure drops in a wide range of pipe network configurations using water as the fluid.

This unit consists of:

Experimental capabilities:

(1294-16-SE)(6).jpg)

Equipment Name: Fluid Friction Measurement Apparatus

Model No: FM100

Click below to see example:Description: This Fluid Friction Measurement Apparatus is designed for students to study the fluid friction head losses of an incompressible fluid flow.

This unit consists of:

Experimental capabilities:

(1220-15-SE)(2).jpg)

Equipment Name: Flowmeter Measurement Apparatus

Model No: FM101

Description: This Flowmeter Measurement Apparatus is designed to introduce students to the operating characteristic of various types of flowmeters.

This unit consists of:

Experimental capabilities:

Equipment Name: Flow Channel and Flume Apparatus

Model No: FM77

Description: This Flow Channel and Flume Apparatus is a bench top unit designed for easy installation. This equipment introduces students to the basic concept of flow characteristics in an open channel.

This unit consists of:

Experimental capabilities:

(1317-16-SE)(2).JPG)

Equipment Name: Rainfall Hydrographs

Model No: FM03

Click below to see example:Description: This Rainfall Hydrographs is a bench scale unit designed to allow students to study different situations of rainfall runoff. Student shall be able to obtain catchment rainfall and runoff values as functions of time.

This unit consists of:

Experimental capabilities:

(1177-14-SE)(4).jpg)

Equipment Name: Flow Channel & Flume Apparatus

Model No: FM27

Description: This Flow Channel & Flume Apparatus is designed for students to study the principles of open channel flow. This unit comes with an open channel made of transparent working section mounted on a strong framework.

This unit consists of:

Experimental capabilities:

(1164-14-GPS)(14).jpg)

Equipment Name: Drainage & Seepage Tank

Model No: FM33

Description: This Drainage & Seepage Tank is designed for students to study the flow through permeable media.

This unit consists of:

Experimental capabilities:

(1331-17-SE)(10).JPG)

Equipment Name: Hydrology Study System Apparatus

Model No: FM512

Click below to see example:Description: This Hydrology Study System Apparatus is designed to demonstrate the run-off hydrographs from model catchments, construction of draw-down curves for one or two well systems in a sand bed , hydraulic gradients in ground water flow, investigation of model stream flow in alluvial material, formation of river features and development over time, and sediment transport, bed load motion, scour and erosion.

This unit consists of:

Experimental capabilities:

Equipment Name: Soil And Water Model Tank

Model No: FM514

Click below to see example:Description: This Soil And Water Model Tank is developed to investigate several aspects of surface irritation and drainage system.

This unit consists of:

a) Dimension (LxWxD) = 1000mm x 25mm x 450mm

b) Front side made from clear see-through material

c) Removable end plates

a) Flood type

b) Drip type

Experimental capabilities:

Equipment Name: Ground Water Flow Unit

Model No: FM531

Click below to see example:Description: This Ground Water Flow Unit is designed for demonstrations of the operating characteristics of three different types of pumps. Sensors are included to monitor pump speed, power, pump head and flow rate, enabling students to produce pump characteristics curves.

This unit consists of:

Experimental capabilities:

(1184-14-SE)(4)modify.jpg)

Equipment Name: Multi-Pump Test Rig

Model No: SE701A-3

Click below to see example:Description: This Multi-Pump Test Rig is designed for demonstrations of the operating characteristics of three different types of pumps. Sensors are included to monitor pump speed, power, pump head and flow rate, enabling students to produce pump characteristics curves.

This unit consists of:

Experimental capabilities:

(1243-15-SE)(2).jpg)

Equipment Name: Multi-Pump Test Rig

Model No: SE701E-6

Click below to see example:Description: This Multi Turbine Test Set is fitted with six pumps and sensors necessary to allow pump characteristics study for different pumps.

This unit consists of:

Experiments on:

Equipment Name: Plunger Pump Demonstration Unit

Model No: FM18-B

Click below to see example:Description: This Plunger Pump Demonstration Unit is designed to demonstrate the working principle of a plunger or ram pump.

This unit consists of:

Experimental capabilities:

(1243-15-SE)(2).jpg)

Equipment Name: Multi Turbine Test Set (3 Turbines)

Model No: SE701E-6

Click below to see example:Description: This Multi Turbine Test Set (3 Turbines) unit is designed to demonstrate the operation of three types of turbines and their performance characteristics such as mechanical power, hydraulic power, hydraulic efficiency and specific speed. The turbines will be driven by a 3kW pump, together with dynamometer and data acquisition system (Optional).

This unit consists of:

Experimental capabilities

Operation and performance characteristics of:

Experiments on:

Equipment Name: Axial Fan Demonstration Unit

Model No: FM51

Click below to see example:Description: This Axial Fan Demonstration Unit consists of a self contained bench top unit with a small scale axial fan and all the necessary instrumentations.

This unit consists of:

Experimental capabilities:

Equipment Name: Centrifugal Fan Demonstration Unit

Model No: FM52

Click below to see example:Description: This Centrifugal Fan Demonstration Unit consists of a self contained bench top unit with a small scale centrifugal fan and all the necessary instrumentations, allowing students to study the effect of different types of fans.

This unit consists of:

Experimental capabilities:

(1336-17-SE)(1).jpg)

Equipment Name: Centrifugal Pump Demonstration Unit

Model No: FM54

Click below to see example:Description: This Centrifugal Pump Demonstration Unit is designed for students to perform the characteristic studies of a centrifugal pump.

This unit consists of:

Experimental capabilities:

Equipment Name: Axial Flow / Turbine Test Rig

Model No: FM60

Click below to see example:Description: This Axial Flow / Turbine Test Rig is designed to study the performance of a pump/turbine in four different modes of operation.

This unit consists of:

Experimental capabilities:

.jpg)

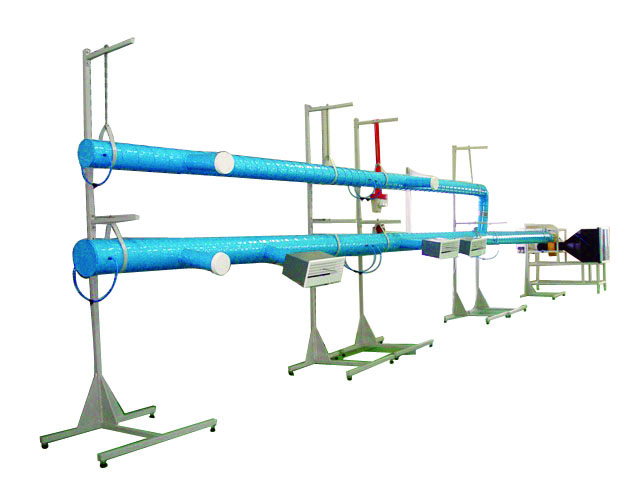

Equipment Name: Air Flow Bench

Model No: FM21

Click below to see example:Description: This Air Flow Bench Unit is designed to demonstrate the principles of compressible fluid flow, the basic unit comes with a motor driven centrifugal fan for studying air flow characteristics.

This unit consists of:

The unit can be used with the following accessories for more comprehensive experiments on air flow:

Experimental capabilities:

Equipment Name: Gas Flow Measurement Bench

Model No: FM120

Click below to see example:Description: This Gas Flow Measurement Bench is designed for students to study the fluid flow of compressible gas.

This unit consists of:

Experimental capabilities:

(1189-14-SE)(1).jpg)

Equipment Name: Ventilation Trainer

Model No: FM801

Click below to see example:Description: This Ventilation Trainer is designed to demonstrate the basic operation of air ventilation.

This unit consists of:

Experimental capabilities:

Equipment Name: Multi Cyclone System

Model No: AP01

Click below to see example:Description: This Multi Cyclone System is designed to demonstrate principles of gas cleaning device in air pollution control. The cyclone separator utilises centrifugal force for dust separation.

This unit consists of:

Experimental capabilities:

(1320-16-SE)(5)ok.jpg)

Equipment Name: Venturi Scrubber System

Model No: AP02

Click below to see example:Description: This Venturi Scrubber System is designed to demonstrate principles of gas cleaning device in air pollution control. Water droplets are created at the venturi throats to trap dust particles from gas stream.

This unit consists of:

Experimental capabilities:

(1320-16-SE)(22).jpg)

Equipment Name: Spray Chamber System

Model No: AP03

Click below to see example:Description: This Spray Chamber System is designed to demonstrate principles of gas cleaning device in air pollution control. Dust particles in the gas stream are trapped by water droplets generated in the spray chamber.

This unit consists of:

Experimental capabilities:

(1320-16-SE)(17)modify.jpg)

Equipment Name: Pulse-Jet Bag Filter System

Model No: AP04

Click below to see example:Description: This Pulse-Jet Bag Filter System is designed to demonstrate principles of gas cleaning device in air pollution control. Dust particles in gas stream are trapped using fabric bag filters

This unit consists of:

Experimental Capabilities:

(1314-16-SE)(12).JPG)

Equipment Name: Electrostatic Precipitator

Model No: AP05

Click below to see example:Description: This Electrostatic Precipitator is designed to demonstrate principles of gas cleaning device in air pollution control. The Electrostatic Precipitator ionizes dust particles and the charged particles are attracted to the collecting plates.

This unit consists of:

Experimental capabilities:

Equipment Name: Basic Cyclone Unit

Model No: AP11

Click below to see example:Description: This Basic Cyclone Unit is designed to demonstrate operation of a basic gas cleaning device in air pollution control.

This unit consists of:

Experimental capabilities:

(1277-16-SE)(2).jpg)

Equipment Name: Sedimentation Study Apparatus

Model No: TR01

Description: This Sedimentation Study Apparatus is designed to demonstrate characteristics of gravitational settling (sedimentation).

This unit consists of:

Experimental capabilities:

i) Effects on settling rates of the followings:

(1277-16-SE)(2)modify.jpg)

Equipment Name: Ion Exchange Unit

Model No: TR02

Description: This Ion Exchange Unit is designed to demonstrate principles of water softening or demineralization process using ion-exchange resins.

This unit consists of:

Experimental capabilities:

Equipment Name: Activated Sludge Sewage Treatment Pilot Plant

Model No: TR04

Description: This Activated Sludge Sewage Treatment Pilot Plant is designed to demonstrate operation of sewage treatment by activated sludge.

This unit consists of:

Instruments & control:

Experimental capabilities:

(1337-17-SE)(21).jpg)

Equipment Name: Filterability Index Unit

Model No: TR05

Description: This Filterability Index Unit is designed to demonstrate water quality test and water quality test procedure for filtration of a suspension.

This unit consists of:

Experimental capabilities:

(1311-16-SE)(2).jpg)

Equipment Name: Aeration Apparatus

Model No: TR06

Description: This Aeration Apparatus is designed to demonstrate the basics of aeration process, which involves the transfer of oxygen from atmosphere into a body of water.

This unit consists of:

Experimental capabilities:

- Water depth and composition

- Design and arrangement of diffusers

- Rate of air supply

- Stirrer speed

(1345-17-SE)(3).jpg)

Equipment Name: Reverse Osmosis Unit

Model No: TR08

Description: This Reverse Osmosis Unit is designed to demonstrate desalination of salt water using RO membrane.

This unit consists of:

- Membrane type: RO (polyamide, 99% rejection of salt)

- Membrane: 12.7 mm (dia.) x 1.2m (L)

Experimental capabilities:

(1336-17-SE)(6).jpg)

Equipment Name: Sedimentation Tank

Model No: TR09

Description: This Sedimentation Tank is designed to demonstrate the hydraulic characteristics and settling efficiencies of a settling basin.

This unit consists of:

Experimental capabilities:

Equipment Name: Flocculation Test Unit

Model No: TR10

Description: This Flocculation Test Unit is designed to demonstrate basic principles of coagulation and flocculation.

This unit consists of:

Experimental capabilities:

(1132-13-SE)(4)modify.jpg)

Equipment Name: Deep Bed Filtration Unit

Model No: TR13

Description: This Deep Bed Filtration Unit is designed to demonstrate the operations of a pilot scale granular filter.

This unit consists of:

Experimental capabilities:

(1158-14-SE)(1).jpg)

Equipment Name: Membrane Test Unit

Model No: TR14

Click below to see example:Description: This Membrane Test Unit is designed to demonstrate separation technique using membrane. This unit is supplied with different types of membrane, namely Reverse Osmosis, Nanofiltration, Utrafiltration and Microfiltration.

This unit consists of:

Pressure/Vacuum pump and tanks are also provided

Experimental capabilities:

Equipment Name: Batch Settling Filtration Column

Model No: TR15

Description: This Batch Settling Filtration Column is designed to demonstrate basic principle of granular filtration.

This unit consists of:

Experimental capabilities:

(1298-16-GPS)(8).jpg)

Equipment Name: Membrane Filtration Unit

Model No: TR16

Click below to see example:Description: This Membrane Filtration Unit is designed to demonstrate separation technique using membrane, which is suitable for heat sensitive materials.

This unit consists of:

Experimental capabilities:

Product flow rate

Process pressure

Process temperature

Equipment Name: Reverse Osmosis Unit

Model No: TR18

Click below to see example:Description: This Reverse Osmosis Unit is designed to demonstrate desalination of salt water using membrane technique.

This unit consists of:

Experimental capabilities:

- Pressure

- Temperature

- Flow rate

Equipment Name: Plate and Frame Filter Press Unit

Model No: TR24

Click below to see example:Description: This Plate and Frame Filter Press Unit is designed to demonstrate filtration process suitable for pharmaceutical, chemical, cosmetic, and food and beverage industries.

This unit consists of:

Experimental capabilities:

Equipment Name: Plate and Frame Filter Pilot Plant

Model No: TR25

Description: This Plate and Frame Filter Pilot Plant is designed to demonstrate operation of a plate and frame filter press. The filter press is suitable for pharmaceutical, chemical, cosmetic and food & beverage industries.

This unit consists of:

- hydraulic hand pump, max. pressure: 7 bar

Experimental capabilities:

(1312-16-SE)(2).jpg)

Equipment Name: Anaerobic Digester

Model No: TR26

Description: This Anaerobic Digester is designed to study effects of various process parameters on performance of anaerobic digestion process for waste water treatment.

This unit consists of:

Experimental capabilities:

(1313-16-SE)(17).jpg)

Equipment Name: Aerobic Digester Unit

Model No: TR28

Description: This Aerobic Digester unit is designed to study effects of various process parameters on performance of aerobic digester.

This unit consists of:

Experimental capabilities:

Equipment Name: Membrane Fabrication Unit

Model No: TR31

Click below to see example:Description: This Membrane Fabrication Unit is designed for student demonstration and research on the fabrication of organic membrane using polymers such as polycarbonate, polyamide, polysulfone, etc.

This unit consists of:

Experimental capabilities:

(1337-17-SE)(1).jpg)

Equipment Name: Corrosion Study Kits

Model No: BP01

Click below to see example:Description: This Corrosion Study Kits is designed to demonstrate the science of corrosion in industrial processes.

This unit consists of:

Experimental capabilities:

Equipment Name: Corrosion Study Kits

Model No: BP01

Click below to see example:Description: This Corrosion Study Kits is designed to demonstrate the science of corrosion in industrial processes.

This unit consists of:

Experimental capabilities:

(1263-15-GPS)modify.jpg)

Equipment Name: Falling Film Absorption Unit

Model No: BP02

Click below to see example:Description: This Falling Film Absorption Unit is designed for experiments on liquid film controlled gas-liquid absorption process.

This unit consists of:

Experimental capabilities:

(1297-16-SE)(4).JPG)

Equipment Name: Liquid Diffusion Coefficient Apparatus

Model No: BP09

Description: This Liquid Diffusion Coefficient Apparatus is designed to measure liquid diffusivity in an equimolar counter diffusion process.

This unit consists of:

Experimental capabilities:

(1297-16-SE)(1).jpg)

Equipment Name: Gaseous Diffusion Coefficient Apparatus

Model No: BP10

Description: This Gaseous Diffusion Coefficient Apparatus is designed to measure molecular diffusivity of gases.

This unit consists of:

Experimental Capabilities:

Equipment Name: Vapour Liquid Equilibrium Unit

Model No: BP16

Click below to see example:Description: This Vapour Liquid Equilibrium Unit is designed to investigate vapour and liquid equilibrium of a binary mixture at pressures up to 10 bar.

This unit consists of:

Experimental capabilities:

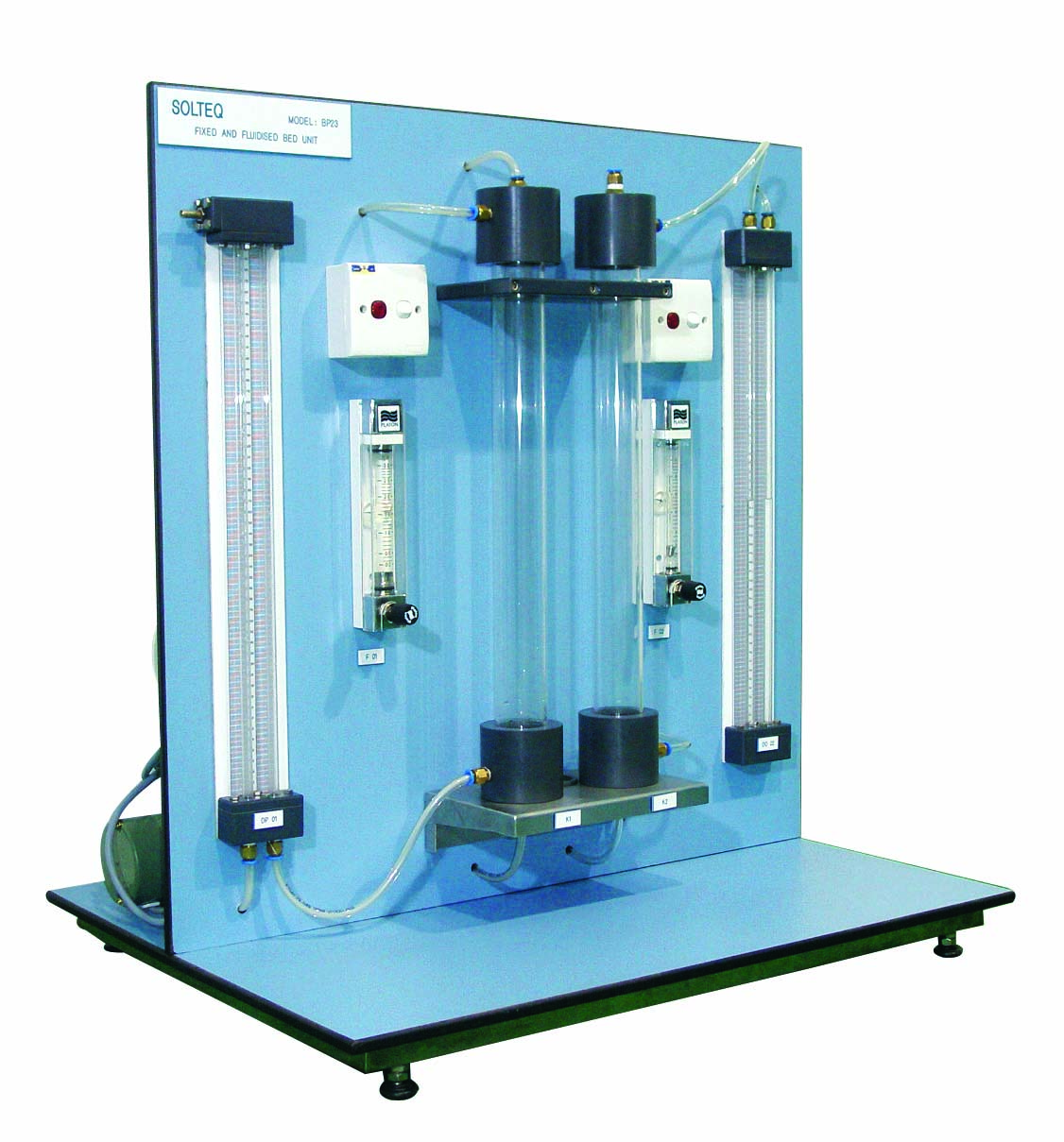

Equipment Name: Fixed and Fluidised Bed Unit

Model No: BP23

Click below to see example:Description: The Fixed and Fluidised Bed Unit is designed to study the behaviour of flow of fluid through both fixed and fluidised bed of solid particles. Differences in flow behaviour can be visualized clearly.

This unit consists of:

Experimental capabilities:

(1346-17-SE)(6).jpg)

Equipment Name: Solid-Liquid Extraction Unit

Model No: BP40

Click below to see example:Description: This Solid-Liquid Extraction Unit is designed to demonstrate the principles of extraction process whereby some components are selectively removed from solid using a suitable solvent.

This unit consists of:

Experimental capabilities:

Equipment Name: Solid-Liquid Extraction Unit

Model No: BP41

Click below to see example:Description: This Solid Liquid Extraction Unit is designed for student demonstration on the extraction process whereby components can be selectively extracted from solid mixtures using a suitable solvent.

This unit consists of:

Experimental capabilities:

Equipment Name: Gas Absorption Unit

Model No: BP50-80

Click below to see example:Description: This Gas Absorption Unit is designed to provide students with a hands-on experience on gas absorption by means of liquids (solvent absorption).

This unit consists of:

Experimental capabilities:

(1285-16-SE)(6).jpg)

Equipment Name: Gas Absorption-Desorption Unit

Model No: BP51-80

Click below to see example:Description: This Gas Absorption-Desorption Unit is designed to provide students with a hands-on experience on gas absorption and desorption.

This unit consists of:

Experimental capabilities:

(1326-17-SE)(4).jpg)

Equipment Name: Liquid-Liquid Extraction Unit (With Solvent Recovery)

Model No: BP60

Click below to see example:Description: This Liquid-Liquid Extraction Unit is designed to demonstrate the principles and operation of liquid-liquid extraction and solvent recovery processes. The mobile unit consists of an extraction system and a solvent recovery system.

This unit consists of:

Experimental capabilities:

(1222-15-SE)(1).jpg)

Equipment Name: Liquid-Liquid Extraction Unit (Without Solvent Recovery)

Model No: BP61

Click below to see example:Description: This Liquid-Liquid Extraction Unit is designed for demonstration of liquid-liquid extraction.

This unit consists of:

Experimental capabilities:

Equipment Name: Rotating Disc Liquid-Liquid Extraction Unit (Without Solvent Recovery)

Model No: BP63

Click below to see example:Description: This Rotating Disc Liquid-Liquid Extraction Unit is designed for demonstration of liquid-liquid extraction using a rotating disc column.

This unit consists of:

Experimental capabilities:

(1285-16-SE) (modify).jpg)

Equipment Name: Double Effect Evaporator

Model No: BP70

Click below to see example:Description: This Double Effect Evaporator is designed to provide students with practical knowledge of evaporation process. Operations of single or double effect climbing film evaporator will be demonstrated.

This unit consists of:

Experimental capabilities:

(1222-15-SE)(1).jpg)

Equipment Name: Continuous Distillation Column Unit

Model No: BP80-50

Click below to see example:Description: This Continuous Distillation Column Unit is designed to demonstrate the principles and operation of continuous distillation also.

This unit consists of:

Experimental capabilities:

Equipment Name: Solids Handling Study Equipment

Model No: BP102

Description: This Solids Handling Study Equipment is designed to demonstrate the characteristics and behaviour of solid particles.

This unit consists of:

Experimental capabilities:

(1282-16-GPS)(22).jpg)

Equipment Name: Crystallisation Unit

Model No: BP123

Click below to see example:Description: This Crystallisation Unit is designed to demonstrate basic principles of crystallization and operations of a crystallizer.

This unit consists of:

Experimental capabilities:

Equipment Name: Gas Adsorbtion Unit

Model No: BP200

Click below to see example:Description: This Gas Adsorbtion Unit is designed to demonstrate the working principles of gas phase adsorption.

This unit consists of:

Experimental capabilities:

Equipment Name: Pressure Swing Adsorbtion Column System

Model No: BP202-A

Click below to see example:Description: This Pressure Swing Adsorption Column System is designed to demonstrate the fundamental and working principles of pressure swing adsorption. Air separation is used as an example.

This unit consists of:

Experimental capabilities:

.jpg)

Equipment Name: Gas-Solid Adsorbtion Column

Model No: BP204

Click below to see example:Description: This Gas-Solid Adsorption Column is designed to study the dynamic adsorption of gas mixtures containing gas CO2 and gas H2S.

This unit consists of:

Experimental capabilities:

Equipment Name: Short Path Distillation System

Model No: BP217

Click below to see example:Description: This Short Path Distillation System is designed for demonstration of separation process for thermal sensitive products. The short residence time and low evaporation temperature process is a great advantage for many high-molecular-weight organic compounds particularly in the fields of chemistry, pharmaceutical and food industry.

This unit consists of:

Experimental capabilities:

(1285-16-SE) (3).jpg)

Equipment Name: Tray Drier

Model No: BP772

Click below to see example:Description: This Tray Drier is designed to demonstrate industrial drying process.

This unit consists of:

Experimental capabilities:

(1215-15-SE)(1).jpg)

Equipment Name: Liquid Mixing Equipment

Model No: FM103

Click below to see example:Description: This Liquid Mixing Equipment is designed for laboratory experiments on solid-liquid and liquid-liquid mixing.

This unit consists of:

Experimental capabilities:

(1310-16-SE)(1).jpg)

Equipment Name: Spray Dryer

Model No: FD20

Description: This Spray Dryer is designed for demonstration of rapid spray drying processes involving aqueous emulsions, solutions, suspensions and colloids. Spray dryers are generally used in the food industry to process fish extracts, heat sensitive materials, milk and egg products, cereals, plant and vegetable extracts, etc.

This unit consists of:

Experimental capabilities:

(1279-16-SE)(3).jpg)

Equipment Name: Decomposition Reactor

Model No: BP90

Click below to see example:Description: This Decomposition Reactor is designed for student experiment on decomposition of sodium bicarbonate.

This unit consists of:

Experimental capabilities:

(1334-17-GPS)(1).jpg)

Equipment Name: Liquid Phase Stirred Tank Reactor

Model No: BP100

Click below to see example:Description: This Liquid Phase Stirred Tank Reactor is designed to demonstrate the behaviour of a stirred tank reactor.

This unit consists of:

Experimental capabilities:

(1295-16-SE)(5).jpg)

Equipment Name: Tubular Flow Reactor

Model No: BP101

Click below to see example:Description: This Tubular Flow Reactor is designed to demonstrate the behavior of a plug flow reactor.

This unit consists of:

Experimental capabilities:

(1295-16-SE)(7).jpg)

Equipment Name: Catalytic Packed Bed Reactor

Model No: BP105

Click below to see example:Description: This Catalytic Packed Bed Reactor is designed for demonstration of catalytic chemical reaction in tubular reactors.

This unit can also be fitted with an air cooled radiator to recycle the heated water.

This unit consists of:

Experimental capabilities:

(1297-16-SE)(1).jpg)

Equipment Name: Packed Bed Catalytic Reactor

Model No: BP106

Click below to see example:Description: This Packed Bed Catalytic Reactor is a bench top unit which is used in demonstration of chemical reaction in tubular reactors.

This unit consists of:

Experimental capabilities:

(1194-14-SE)modify.jpg)

Equipment Name: CSTR in Series

Model No: BP107

Click below to see example:Description: This CSTR in Series is designed to demonstrate the dynamic behavior of reaction in series

This unit consists of:

Experimental capabilities:

(1288-16-SE)(1).jpg)

Equipment Name: Batch Reactor

Model No: BP109

Click below to see example:Description: This Batch Reactor is designed to demonstrate the behavior of a batch reactor.

This unit consists of:

Experimental capabilities:

(1297-16-SE)(1).jpg)

Equipment Name: RTD Studies in Packed Bed Reactor

Model No: BP112

Description: This RTD Studies in Packed Bed Reactor is designed to demonstrate principles of RTD in a packed bed reactor.

This unit consists of:

Experimental capabilities:

(1224-15-SE)(1).jpg)

Equipment Name: Reactor Service Unit + 3 Reactors

Model No: BP150

Click below to see example:Description: This Reactor Service Unit + 3 Reactors is designed to demonstrate the behavior of different types of reactors using a common service unit with interchangeable reactors.

This unit consists of:

Experimental capabilities:

Equipment Name: Benchtop CSTR in Series

Model No: BP151

Click below to see example:Description: This Benchtop CSTR in Series is designed to introduce students to the dynamic behavior of reactors in series.

This unit consists of:

Experimental capabilities:

(1166-14-SE)(7)modify.jpg)

Equipment Name: Fixed Bed Adsorption Reactor

Model No: BP208

Click below to see example:Description: This Fixed Bed Adsorption Reactor is designed to demonstrate the principles of adsorption of CO2 from a binary gas mixture onto the surface of a solid adsorbent (activated carbon). The process takes place in a fixed bed column.

This unit consists of:

Experimental capabilities:

(1222-15-SE)(1).jpg)

Equipment Name: Reactor Basic Unit (CSTR)

Model No: BP400

Click below to see example:Description: This Reactor Basic Unit (CSTR) is designed to introduce students to the behavior of a CSTR reactor.

This unit consists of:

Experimental capabilities:

copy.jpg)

Equipment Name: Reactor Basic Unit (Batch)

Model No: BP409

Click below to see example:Description: This Reactor Basic Unit (Batch) is designed to introduce students to the behavior of a batch reaction.

This unit consists of:

Experimental capabilities:

Equipment Name: Air Conditioning Laboratory Unit

Model No: AC01

Click below to see example:Description: This Air Conditioning Laboratory Unit is designed to demonstrate the working principles of air conditioning system.

This unit consists of:

Experimental capabilities:

.jpg)

Equipment Name: Water Cooled Package Air Conditioner

Model No: AC155

Click below to see example:Description: This Water Cooled Package Air Conditioner is installed with industrial type components to demonstrate the working principle of an actual air conditioning system.

This unit consists of:

Experimental capabilities:

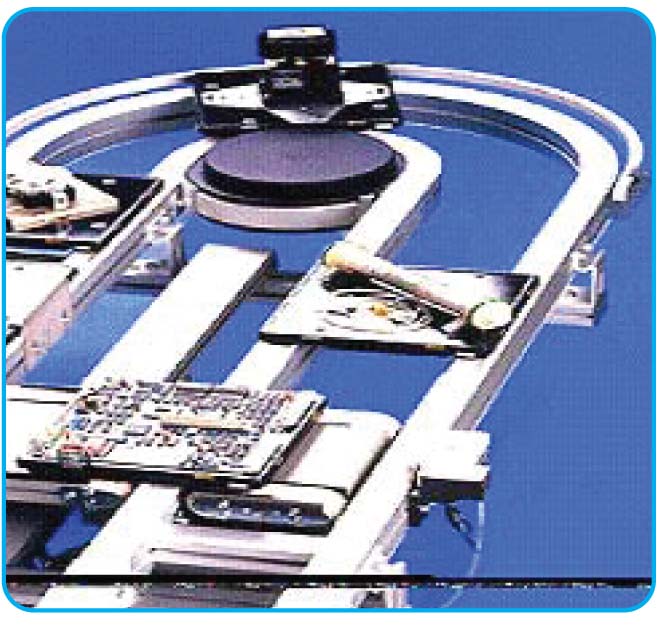

Equipment Name: Conveyor Belt Trainer

Model No: BS01

Description: This Conveyor Belt Trainer is designed to incorporate a conveyor, which carries material, components or assemblies on carrier plates call pallets. The conveyor has a continuously moving belt to transport the pallets to positioning stations where the pallet is stopped and locked into position, ready for work to be done with the material on the pallet. The closed loop pallet conveyor is fully compatible with the ranges of Robots, Machine Tools, ASRS and other hardware elements. It is integrated with the rest of the system software through the use of a special device driver program which supervise the movements of all pallets.

Equipment Name: CCTV System Demonstration

Model No: BS04

Description: This CCTV System Demonstration Unit is designed to demonstrate the students a PC based Digital Surveillance system in the CCTV industry. The unit consists of a video surveillance card, a PC install with card’s software, speed dome camera, PTZ camera and a fixed dome camera. It has the abilities to reduce and prevent crime, antisocial behaviours and assist in criminal investigation.

(120-14-SE)(1).jpg)

Equipment Name: Corrosion Study Unit

Model No: BP01

Click below to see example:Description: This Corrosion Study Unit is designed to demonstrate the science of corrosion in industrial processes.

This unit consists of:

Experimental capabilities:

(1328-17-SE)Photos(18).jpg)

Equipment Name: Industrial Piping and Valves Training System

Model No: IPTS02